Leave Your Message

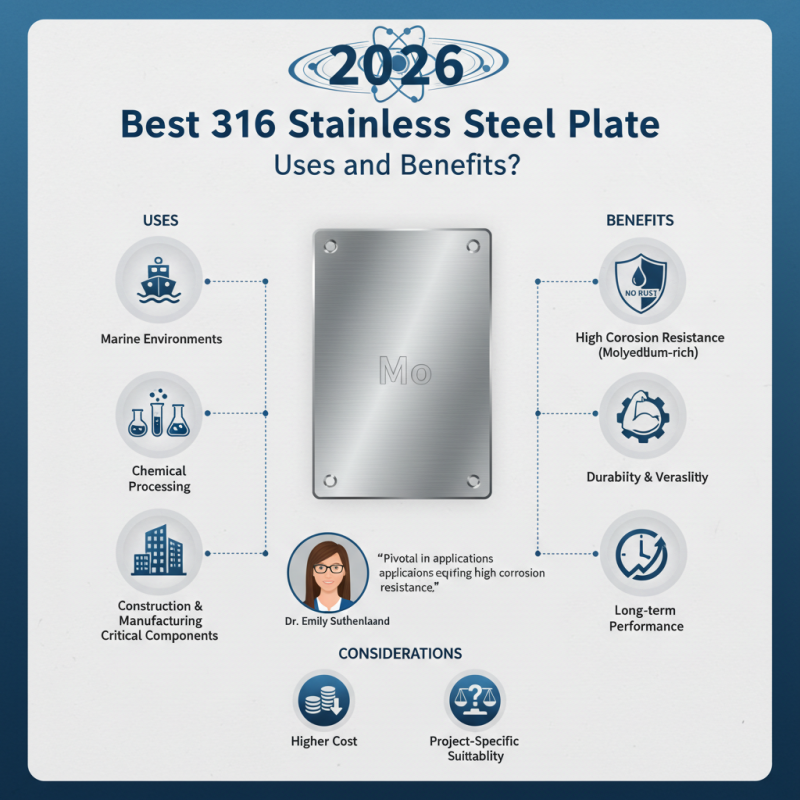

In the world of construction and manufacturing, the "316 Stainless Steel Plate" holds a reputation for its versatility and durability. According to industry expert Dr. Emily Sutherland, "The 316 Stainless Steel Plate is pivotal in applications requiring high corrosion resistance." This type of stainless steel contains molybdenum, giving it superior resistance to harsh environments.

Today, many industries rely on 316 Stainless Steel Plates for critical components. These materials are widely used in marine environments and chemical processing. Their ability to withstand salty and acidic conditions makes them invaluable. While these plates offer numerous benefits, it’s important to remember that not all applications may be suitable. For instance, in low-stress environments, simpler materials could be equally effective.

Exploring the uses of 316 Stainless Steel Plates reveals both advantages and considerations. Their high cost, for example, can be a hurdle for some projects. Long-term performance and maintenance must also be factored in. Ultimately, each project requires careful evaluation to determine if 316 Stainless Steel Plates are the right choice.

316 stainless steel is renowned for its excellent corrosion resistance and durability. Composed mainly of iron, nickel, and chromium, it performs well in various environments. This alloy is particularly effective against pitting corrosion, making it ideal for marine applications. Its resistance to high temperatures, up to 870°C, is also remarkable. According to industry reports, 316 stainless steel is often used in food processing, chemical processing, and pharmaceutical sectors.

Tip: Always check the specific application needs before choosing materials.

Despite its advantages, 316 stainless steel can be more expensive than other types. This cost factor may deter some users. It's crucial to weigh the benefits against the budget. Research shows that the long-term durability often offsets the initial investment. Evaluating lifecycle costs is essential in such decisions.

Tip: Explore different grades to find the right balance of cost and performance.

While 316 stainless steel offers many benefits, it may not be suitable for every situation. For example, in extremely high-saline environments, it might require additional protection. Users should stay informed about the limitations and possibilities of this alloy. Regular performance assessments can help identify potential downtimes or maintenance needs.

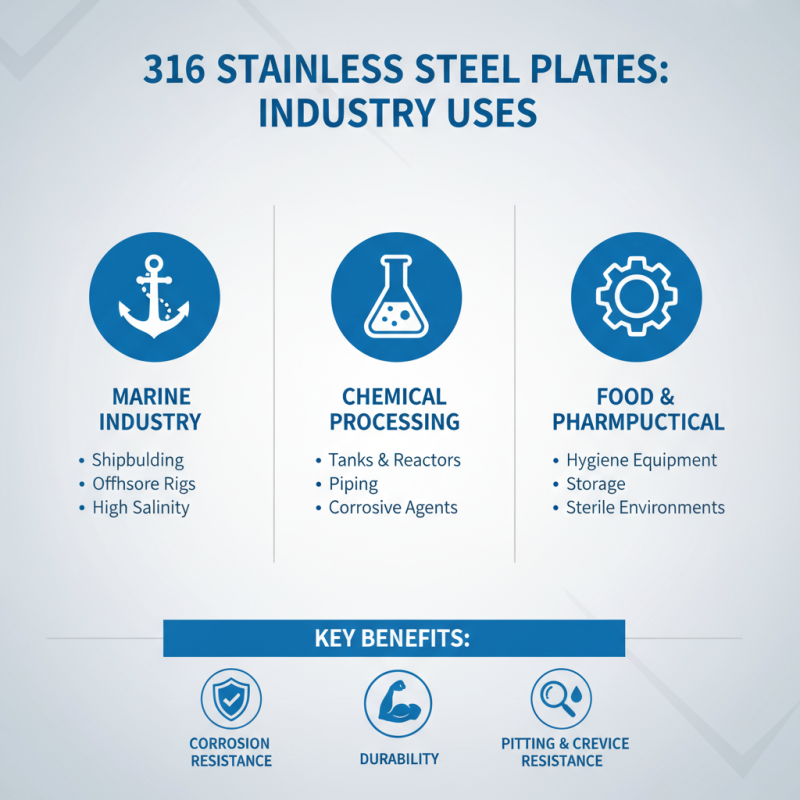

316 stainless steel plates are widely used across various industries due to their excellent corrosion resistance and durability. In the marine industry, for instance, these plates are essential. They withstand harsh environments and high salinity levels. A recent industry report indicates that 316 stainless steel's resistance to pitting and crevice corrosion is critical for shipbuilding and offshore applications.

In the food processing sector, 316 stainless steel plates play a pivotal role in equipment manufacturing. They meet sanitation standards and can resist rust and corrosion. According to a 2023 study, using 316 stainless steel in food processing equipment reduces contamination risks. This is vital for maintaining food safety. However, the cost of these plates can be a drawback for smaller operations, leading to budget constraints.

The chemical industry also relies on 316 stainless steel plates. They handle aggressive chemicals and extreme heat. Data from a recent report highlights that 316 stainless steel maintains its integrity under these conditions, which is crucial for plant safety. Still, some manufacturers struggle with sourcing high-quality plates. Inconsistent supply chains can lead to project delays. This effect brings attention to the need for more reliable material sourcing in the industry.

316 stainless steel plates are a popular choice in many manufacturing processes. They offer excellent resistance to corrosion, making them ideal for harsh environments. This type of stainless steel contains molybdenum, which enhances its strength and durability. Thus, it is often used in chemical and marine applications.

One of the main advantages of 316 stainless steel is its ability to withstand extreme temperatures. This property makes it suitable for applications involving heat and stress. The plates also maintain their integrity under varying conditions, which is essential in food processing and medical equipment. However, the cost can be higher than other stainless steel grades.

Using 316 stainless steel plates can also lead to some challenges. While they are strong, they are not immune to scratches and dents. Over time, maintenance may be required to keep them in top condition. Balancing cost and quality is crucial for manufacturers. Every choice has trade-offs, and stainless steel is no exception.

When comparing 316 stainless steel to other stainless alloys, several factors emerge.

316 stainless steel is known for its excellent corrosion resistance, particularly in marine environments.

This makes it ideal for applications like boat fittings and chemical processing equipment.

Its molybdenum content enhances durability even in harsh settings.

In contrast, 304 stainless steel, while popular, may not perform as well under extreme conditions.

It lacks the same degree of resistance to chlorides, making it less suitable for coastal projects.

Other alloys, such as 430 stainless steel, offer lower corrosion resistance.

They can tarnish quickly in humid situations. This highlights a crucial trade-off: cost versus performance.

Many industries lean towards 316 steel because of its reliability.

However, there are scenarios where lower-grade alloys might suffice, resulting in potential cost savings.

It's essential to assess each project's specific needs carefully.

Recognizing the limitations of each material can lead to better decisions.

Balancing factors like environment and budget should never be overlooked.

The use of 316 stainless steel plates is evolving. As industries demand more versatility, innovations are emerging. These plates are known for their excellent corrosion resistance. This feature makes them ideal for marine applications and chemical processing. Yet, there is always room for improvement in material properties and manufacturing processes.

Future trends indicate a push towards sustainability. Manufacturers are exploring eco-friendly production methods. Incorporating recycled materials is becoming more common. However, challenges remain in balancing cost and quality. There’s also a need to better understand how these plates perform under extreme conditions. Research is ongoing to enhance their resilience and durability, especially in harsh environments.

Design flexibility is another area of innovation. 316 stainless steel plates can be customized for various uses. This adaptability can lead to better performance in specific applications. Yet, the reliance on innovation also poses risks. Not all new methods are proven, and missteps can lead to failures. Continuous evaluation and testing are vital for maximizing the benefits of these materials.