Leave Your Message

When selecting the best options for a 316 Stainless Steel Channel, expertise is crucial. Industry expert Dr. Emily Carter once stated, “The right material makes all the difference in structural integrity.” This highlights the importance of making informed choices.

Understanding the specific applications of 316 Stainless Steel Channel is vital. This alloy is highly resistant to corrosion, making it ideal for harsh environments. However, not all channels are created equal. It is essential to consider factors like dimensions, load capacity, and environmental exposure when making a decision.

Choosing the right channel may seem straightforward, yet it requires careful reflection. Many overlook the impact of quality. A poor choice can lead to severe structural failures. Hence, paying attention to the details is key to achieving long-term success in your projects involving 316 Stainless Steel Channel.

316 stainless steel is notable for its exceptional corrosion resistance. This type of stainless steel contains nickel and molybdenum, enhancing its performance in high-temperature and high-saline environments. Data from the International Stainless Steel Forum indicates that 316 stainless steel offers superior strength and durability compared to many other materials, making it ideal for varied applications, including marine and chemical industries.

The composition typically consists of approximately 16% chromium, 10% nickel, and 2% molybdenum. These elements contribute to its ability to withstand pitting, which can be crucial in harsh settings. However, while its resistance to oxidation is impressive, 316 stainless steel is not completely maintenance-free. Over time, it can develop superficial rust spots, especially in areas with high moisture exposure. Regular cleaning and inspections are recommended to maintain its aesthetic appeal and functionality.

Choosing the right 316 stainless steel channel requires understanding these properties. Not all types are created equal. Factors like thickness, width, and finish must be considered. Users may overlook the importance of these details, leading to potential performance issues. A thorough analysis of the project requirements is essential before making a decision. A well-informed choice can ultimately enhance the longevity and reliability of the final product.

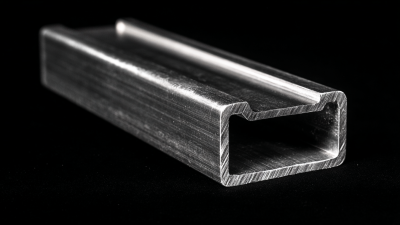

When it comes to selecting the right channel sizes and shapes for your project, several factors come into play. Stainless steel channels are versatile and robust, making them a popular choice in many applications. However, not all channels are created equal. The right size and shape can significantly impact both performance and aesthetics.

Consider the specific needs of your project. Are you focusing on load-bearing capabilities or simply aesthetics? A wider channel may distribute weight better but could be overkill for a project requiring minimal support. Additionally, the shape can influence installation and overall appearance. For instance, a U-shaped channel can enhance stability. Meanwhile, a C-shaped channel may offer a sleek look.

It’s also essential to reflect on your project’s environment. If it’s exposed to harsh conditions, opt for a thicker channel for added durability. Sometimes, people overlook the nuances of channel selection, leading to mismatches between design expectations and material performance. Investing time in evaluating these details can save future headaches. Look closely at the dimensions and consider making adjustments. Making a thoughtful choice now can prevent complications later on.

When considering corrosion resistance, 316 stainless steel is a popular option due to its molybdenum content. This alloy offers superior protection against chloride environments, making it ideal for marine applications. According to a study by the American Institute of Steel Construction (AISC), 316 stainless steel resists pitting and crevice corrosion, particularly in coastal areas.

However, it’s important to note that even 316 stainless steel can face challenges. In highly aggressive environments, such as those with high levels of salt or acid, its performance can decline. Some studies reveal that after prolonged exposure, localized corrosion may still occur. It’s critical to assess the specific environment and conditions when selecting materials.

Additionally, finish and surface treatment can significantly impact corrosion resistance. Electropolishing, for instance, enhances surface smoothness. Yet, not all finishes are equally effective in all settings. Evaluating environmental factors, such as temperature and humidity, is essential. This diligence can lead to better material choices and prevent costly failures in structural integrity.

When assessing the cost-effectiveness of 316 stainless steel channels, consider several important factors. The first is the initial investment. While 316 stainless steel generally costs more than other materials, its corrosion resistance can result in lower maintenance costs. If the environment is harsh, this could mean significant savings over time.

Tips for choosing the best options include looking at the thickness and weight of the channel. Thicker materials generally offer better durability. A heavier channel may cost more upfront, but it can save money in the long run by reducing replacements. Evaluate your project’s specific needs carefully.

Consider the supplier’s reputation and service. A reliable supplier can provide insights that save you time and money. Make sure to ask about lead times and any volume discounts. Ultimately, the right decision will depend on balancing immediate costs with long-term benefits, which can be challenging. Take the time to reflect on different scenarios before making a choice.

When looking for suppliers and manufacturers of 316 stainless steel channels, quality should be your primary concern. Start by researching potential companies. A good reputation is crucial. Customer reviews can provide insight into their reliability. Check industry-specific forums for experiences shared by others. Feedback from previous clients helps gauge product excellence.

Consider visiting the supplier's facilities if possible. This direct observation can reveal a lot about their operational standards. Ask about their sourcing methods and material certifications. A trustworthy supplier will gladly share this information. Some may hesitate, which could be a red flag. Be prepared to walk away if you sense any hesitation.

Don't forget to inquire about their customer service. Efficient communication is key in any business relationship. Suppliers should respond promptly and professionally. This can indicate how they handle issues that may arise later. It's essential to work with a partner who values transparency and responsiveness. The right supplier will elevate your projects and ensure your satisfaction.