Leave Your Message

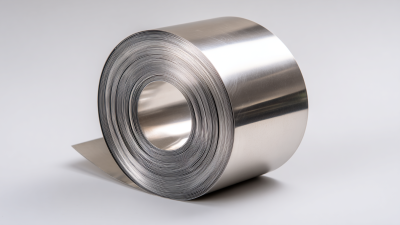

The use of 304 Stainless Steel Belt has transformed various industries significantly. According to a report by Smith & Associates, the global demand for stainless steel in manufacturing surged by over 15% in the past two years. This increase emphasizes the importance of high-quality materials like the 304 Stainless Steel Belt. Industry expert Dr. Emily Tran notes, "The durability and resistance to corrosion make 304 Stainless Steel an essential choice for many applications."

With its excellent mechanical properties and adaptability, 304 Stainless Steel Belt is favored in food processing, automotive, and aerospace industries. Its non-reactive nature ensures safe handling of various materials. However, it is crucial to consider the right specifications for each application to avoid usability issues. Not all stainless steel belts are created equal, and missteps can lead to significant operational challenges.

In a landscape where efficiency is key, the benefits of 304 Stainless Steel Belt are evident. It offers exceptional value through longevity and reliability. Yet, organizations must reflect on their choices and ensure proper material selection aligns with their specific needs.

304 stainless steel belts are widely appreciated for their exceptional corrosion resistance. This alloy contains 18% chromium and 8% nickel, giving it a unique ability to withstand rust and oxidation. According to the International Stainless Steel Forum, around 70% of stainless steel produced is 304 grade, highlighting its popularity in various industries.

In environments with high humidity or exposure to chemicals, 304 stainless steel belts excel. They resist chlorides, making them suitable for food processing and marine applications. A study published in the Journal of Materials Science indicates that 304 stainless steel shows over 85% resistance to corrosion over a five-year period, maintaining structural integrity even in harsh conditions.

However, not all environments are friendly. While 304 stainless steel is robust, it may not be ideal for highly acidic settings. Continuous exposure to saltwater or certain chemical compounds can compromise its performance. Industries must consider these factors when selecting materials. Understanding the limitations can lead to better material choices and safer applications.

| Benefit | Description |

|---|---|

| Corrosion Resistance | Excellent resistance to corrosion from a wide range of chemicals and environmental conditions. |

| Durability | Robust material that withstands wear and tear, maintaining structural integrity over time. |

| Temperature Resistance | Can operate effectively at both high and low temperatures without losing strength. |

| Aesthetic Appeal | Offers a bright, attractive finish that enhances the visual appeal of products. |

| Low Maintenance | Requires minimal upkeep due to its non-reactive nature and resistance to rust. |

| Eco-Friendly | Made from recyclable materials and can be reused, contributing to sustainability. |

| Cost-Effectiveness | Offers a good balance between cost and performance, making it an economical choice. |

| Versatility | Suitable for a wide range of applications in various industries, including food and chemical processing. |

| Hygienic Properties | Non-porous surface prevents bacterial growth, making it ideal for sanitary applications. |

| Strength | High tensile strength and toughness provide resistance to deformation under stress. |

Stainless steel 304 is renowned for its high durability and longevity, making it an ideal choice for various applications. This material contains a significant percentage of chromium and nickel. These elements enhance its corrosion resistance. According to the International Stainless Steel Forum (ISSF), 304 stainless steel can withstand temperatures ranging from -196°C to 800°C. This broad temperature tolerance makes it suitable for diverse environments.

In industrial settings, the use of 304 stainless steel belts can reduce maintenance costs. Less frequent replacements lead to savings over time. A report from the Finnish Institute of Marine Research indicates that stainless steel components can last more than 50 years in marine applications, highlighting durability. However, improper choices in finish and fabrication can lead to imperfections. These may compromise corrosion resistance. It is essential to understand the material's limitations to achieve optimal performance.

Furthermore, while 304 stainless steel is strong, it can be prone to stress corrosion cracking in certain environments. Exposure to chlorides is a notable risk, raising concerns in specific applications. Reflecting on real-world usage, engineers need to ensure optimal conditions for this material to truly realize its benefits. Understanding the nuances helps in achieving longevity and better performance over time.

304 stainless steel belts are renowned for their versatility in numerous applications. These belts are common in food processing, automotive, and material handling industries. According to a report by the Stainless Steel World, the demand for 304 stainless steel in industrial applications is expected to grow by 5% annually until 2025. This growth highlights its importance in creating durable and reliable products.

These belts excel in environments where corrosion resistance is crucial. They can withstand harsh chemicals and temperatures. For instance, in food processing, 304 stainless steel belts are hygienic, which complies with food safety standards. A study by the American Society of Mechanical Engineers emphasizes that proper material selection can enhance product longevity by up to 50%. However, the maintenance of these belts should not be overlooked. Regular inspections are necessary to prevent wear and tear.

Despite their advantages, not all applications may benefit equally from 304 stainless steel. For high-temperature scenarios, other materials might be more appropriate. It’s essential to assess specific needs before making a decision. The versatility of 304 stainless steel belts is evident, yet challenges in ensuring maximum effectiveness should be acknowledged. Users must remain informed and proactive.

Maintaining and cleaning 304 stainless steel products can be surprisingly easy. This material resists corrosion and staining better than many alternatives. A simple wipe with a damp cloth often suffices. For tougher stains, a mild detergent works wonders. Just remember to rinse thoroughly afterward to avoid leaving any residue.

However, neglecting regular cleaning can lead to dullness. Over time, food residue and grease may build up. It’s important to act quickly to prevent this. For occasional deep cleaning, a vinegar solution can restore shine. Many appreciate the low maintenance yet occasionally overlook this aspect. A little reflection on cleaning habits can enhance the longevity of these products.

The ease of cleaning often makes 304 stainless steel a top choice in kitchens. Its resilience means less frequent replacement too. Yet, users might find themselves complacent, forgetting that proactive care is key. Regular attention can ensure these products remain aesthetically pleasing and functional. It's worth considering how small efforts can lead to significant benefits over time.

304 stainless steel belts offer great value over time. Their resistance to corrosion makes them ideal for various environments. Many industries prefer these belts due to their durability. They require less frequent replacement, which reduces long-term costs. The initial investment may seem high, but savings can accumulate quickly.

In some cases, users find maintenance challenges. Regular cleaning is necessary to prevent buildup. Neglecting this can lead to increased wear and tear. However, when properly maintained, 304 stainless steel belts excel in longevity. They withstand harsh conditions and continue to perform efficiently. This reliability makes them a top choice for many applications.

Another aspect to consider is the environmental impact. Using durable materials like 304 stainless steel reduces waste. Fewer replacements mean less material in landfills. While the upfront cost can be daunting, the benefits often outweigh this concern. With careful management, these belts can positively influence overall operations.