Leave Your Message

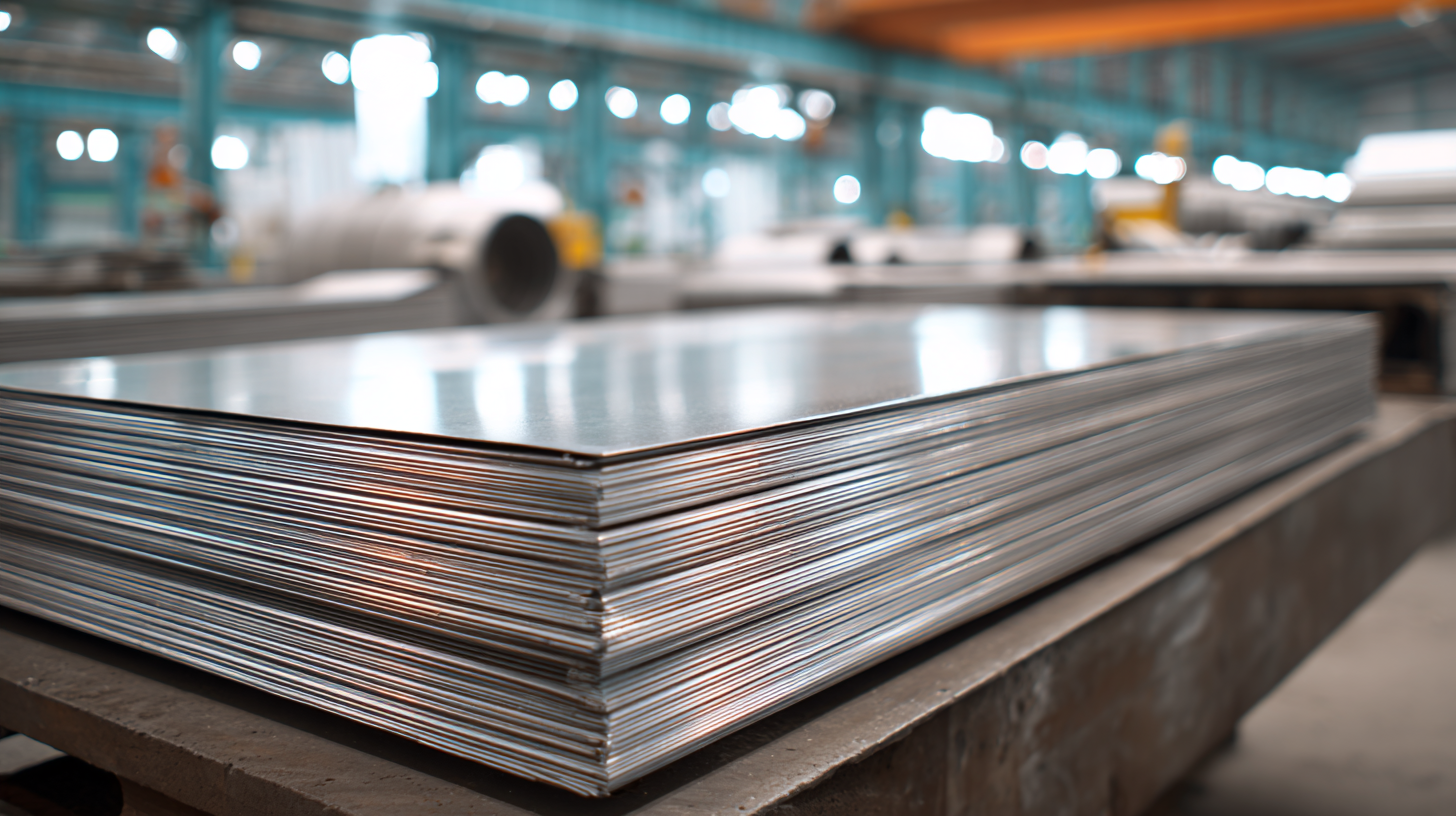

In the competitive landscape of materials manufacturing, the significance of high-quality raw materials cannot be overstated. Among these, the 316 Stainless Steel Plate stands out for its exceptional properties, making it the preferred choice across various industries including aerospace, automotive, and food processing. According to a recent market analysis by ResearchAndMarkets, the global demand for stainless steel is projected to reach 52 million metric tons by 2025, with 316 stainless steel grades anticipated to account for a significant portion of this growth due to their superior corrosion resistance and durability. China's advances in manufacturing processes and adherence to international quality standards position it as a leading supplier of 316 Stainless Steel Plates, driving global recognition while meeting stringent industry requirements. As businesses seek to enhance product performance and longevity, understanding the benefits of 316 Stainless Steel Plate is essential for those aiming for excellence in production.

The rising demand for 316 stainless steel plates in global markets is reflective of the material’s exceptional durability and corrosion resistance, making it a vital choice across numerous industries. As countries prioritize sustainable infrastructure and advanced manufacturing, the need for high-quality materials like 316 stainless steel is surging. In particular, the robust performance of 316 stainless steel plates under extreme conditions has made them a preferred option for applications in the automotive, aerospace, and marine sectors.

Furthermore, the stainless steel market is projected to experience significant growth, with revenue expected to climb, indicating an optimistic outlook for manufacturers and suppliers. Recent positive trends in the stainless steel futures market highlight a strengthening demand, driven by both comprehensive supply-demand dynamics and favorable policy factors. As global markets increasingly recognize the importance of quality raw materials, sourcing from reputable suppliers, especially those in regions such as China, will be crucial for maintaining competitive advantage and achieving excellence in production standards.

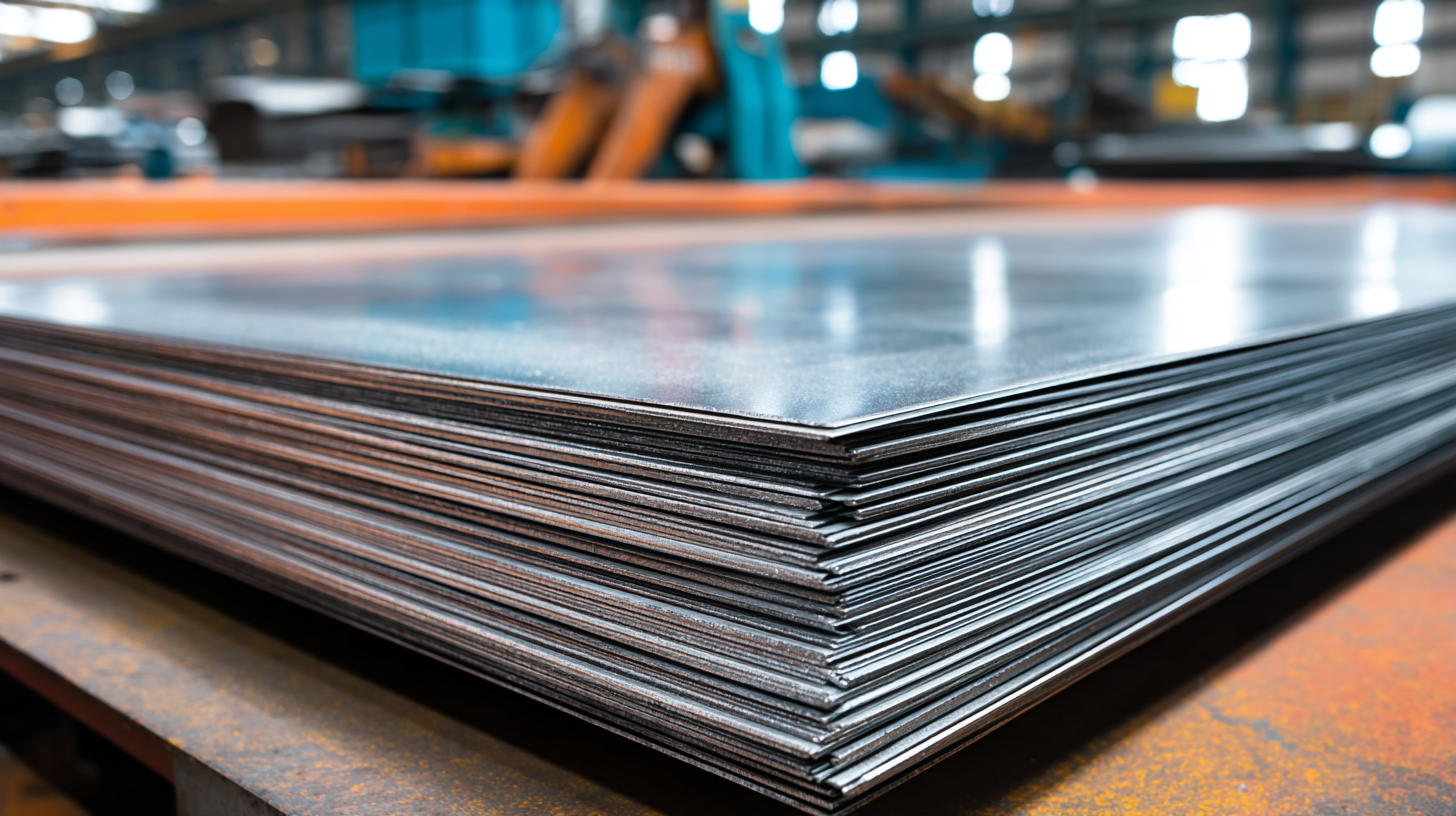

The 316 stainless steel plate has emerged as a benchmark material across various industries due to its exceptional characteristics. Known for its impressive corrosion resistance, high strength, and excellent weldability, this alloy is preferred in environments that demand durability and longevity. The ability to withstand extreme temperatures and harsh chemicals makes 316 stainless steel particularly valuable in the chemical, marine, and food processing sectors. Recent advancements, such as additive manufacturing techniques, have further enhanced its versatility, allowing for the creation of complex structures tailored to specific applications.

Tips: When choosing 316 stainless steel for your projects, consider the specific environmental conditions it will face. For instance, incorporating heat treatments can improve its fatigue performance, as evidenced by recent studies on the effects of build orientations. Moreover, understanding the microstructural changes that occur during fabrication will help you optimize the mechanical properties of your components, consequently enhancing their functionality in demanding applications.

In addition, it’s crucial to stay updated on the latest research developments in stainless steel processing. Innovations in techniques like laser powder bed fusion have shown promising results in controlling defects while enhancing mechanical attributes. Being well-informed allows industries to leverage the latest technologies in 316 stainless steel to maximize efficiency and performance in their operations.

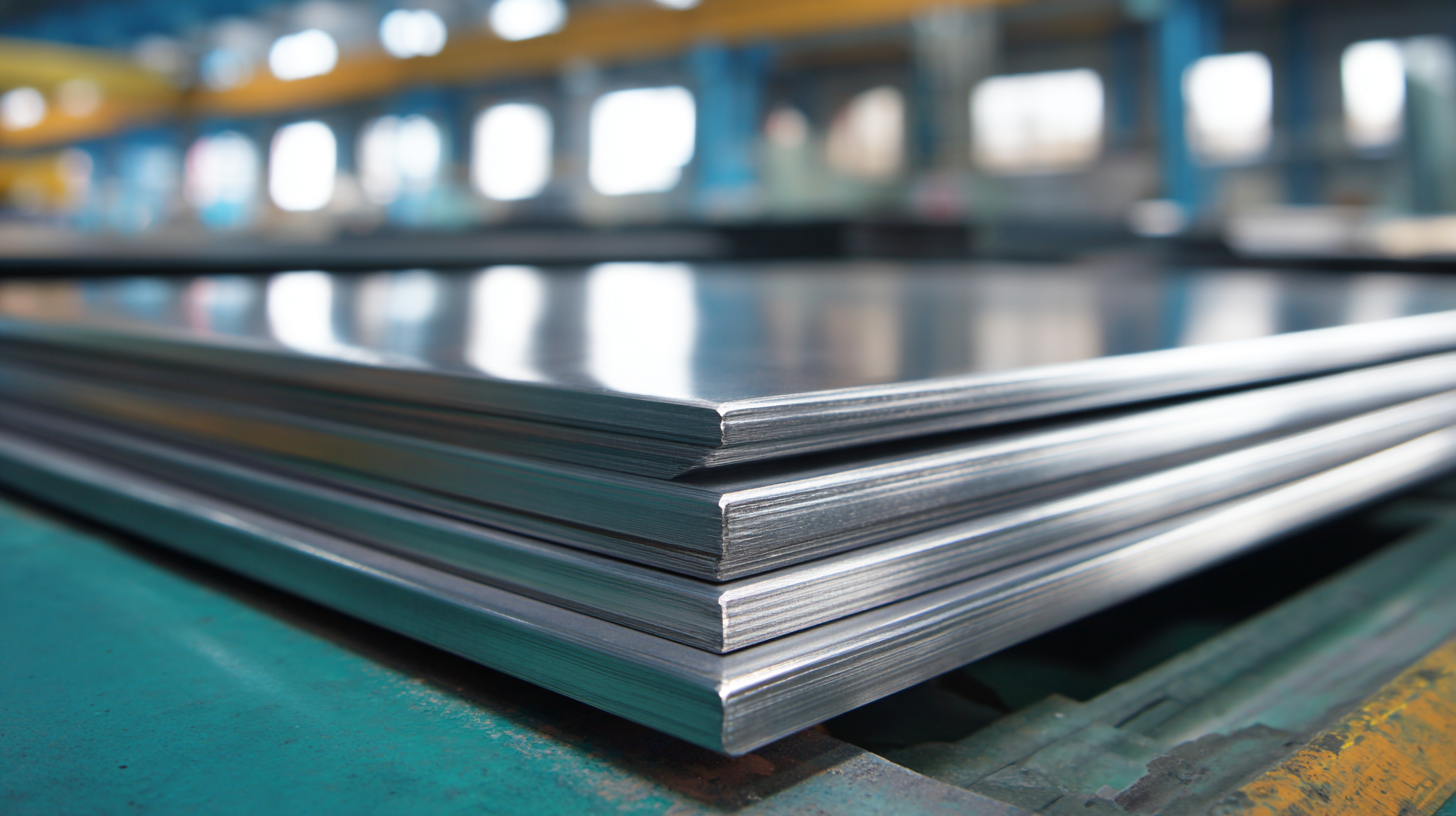

China has established itself as a powerhouse in the production of 316 stainless steel, a material renowned for its exceptional corrosion resistance and strength. As of 2023, China dominates the global market, accounting for nearly 50% of the world’s total stainless steel output. This significant market share underscores China's critical role in supplying high-quality 316 stainless steel plates, which are increasingly in demand for various applications, including automotive, aerospace, and marine industries.

The stainless steel sheet market is noteworthy for its ongoing price increases, driven by rising production costs and surcharges. Reports indicate that base prices for stainless steel have been consistently climbing, with producers adjusting prices upward for February deliveries. Additionally, the escalating nickel prices—which are a key component in stainless steel production—further compound these challenges. The anticipated growth in the stainless steel sector points towards a robust demand for 316 stainless steel sheets, projecting a compound annual growth rate (CAGR) of 4.5% through the next five years. As market dynamics evolve, companies and consumers alike are increasingly leaning on the reliability and superior quality of Chinese 316 stainless steel to meet their needs.

The following chart illustrates the annual production of 316 stainless steel in various countries, showcasing China's dominance in the global market.

In the competitive realm of stainless steel manufacturing, maintaining stringent quality control standards is essential for gaining global recognition. The Bureau of Indian Standards (BIS) has emphasized the necessity of robust protocols that ensure the integrity of stainless steel products. Notably, a pivotal report indicates that the automotive door sills market is projected to reach USD 7.6 billion by 2024, driven by a compound annual growth rate (CAGR) of 7.4% through 2034. This showcases the growing demand for high-quality materials in sectors where stainless steel plays a crucial role, highlighting the importance of quality compliance in production processes.

Amidst these developments, the Steel Ministry's push for stricter regulations on non-standard steel imports signals a broader industry trend towards enhanced quality assurance. The increasing adoption of advanced technologies, such as Handheld XRF for metal analysis, has revolutionized quality control measures across the manufacturing landscape. This technology facilitates manufacturers in verifying that their materials meet the stringent requirements necessary for high-performance applications, ensuring that products made from 316 stainless steel not only meet domestic standards but are also positioned for international competitiveness. As manufacturers in China strive for excellence, embracing a culture of quality management will be pivotal in fulfilling global market demands.

The use of 316 stainless steel has experienced a significant surge in recent years due to its remarkable corrosion resistance and durability. As industries worldwide seek solutions for demanding environments, the adoption of this material is expanding across sectors such as marine, chemical, and food processing. The ability to withstand harsh climates, including salty and acidic conditions, positions 316 stainless steel as an essential choice for manufacturers aiming for both quality and longevity in their products.

Innovations in the manufacturing processes of 316 stainless steel are paving the way for enhanced efficiency and sustainability. Advanced techniques, such as 3D printing and precision casting, are now being integrated into the production of stainless steel plates, minimizing waste and energy consumption. Furthermore, the development of eco-friendly alloys and the implementation of recycling practices are setting new standards for responsible manufacturing. As these trends continue to evolve, industries can expect not only improved material performance but also a significant reduction in their environmental footprint, paving the way for a more sustainable future in stainless steel usage.

| Aspect | Current Trends | Future Innovations | Impact on Industry |

|---|---|---|---|

| Material Composition | High corrosion resistance and strength | Enhanced alloying techniques | Improved durability and longevity |

| Manufacturing Process | Traditional processes with slight automation | AI-driven manufacturing | Increased efficiency and precision |

| Market Demand | Steady growth in construction and automotive sectors | Rising demand in renewable energy | Broadening application range |

| Sustainability Efforts | Recycling and reduced waste initiatives | Innovative eco-friendly production methods | Enhanced corporate social responsibility |

| Global Recognition | Strengthened trade relationships | Increased international standards compliance | Reputation and market competitiveness |