Leave Your Message

In the world of lifting solutions, the right equipment matters. Crane Ceiling Rope plays a vital role in ensuring safety and efficiency. Industry expert John Smith once said, "The right rope can make all the difference in your lifting tasks." His insight highlights the importance of selecting quality materials.

Choosing the best crane ceiling rope involves understanding your specific needs. Not all ropes are created equal. Some may lack the strength required for heavy loads or be prone to wear and tear. It’s crucial to consider factors like load capacity and durability.

Many users overlook essential features when selecting a crane ceiling rope. This can lead to accidents or inefficiencies. The right choice will not only improve performance but can also offer peace of mind. Evaluate the options carefully. Remember, lifting safely is non-negotiable.

Crane ceiling rope systems are essential in various industries, from construction to manufacturing. These systems facilitate lifting heavy loads efficiently and safely. According to a recent industry report by the Occupational Safety and Health Administration (OSHA), about 70% of lifting-related accidents involve improper rigging practices. This underscores the importance of understanding crane ceiling ropes and their applications.

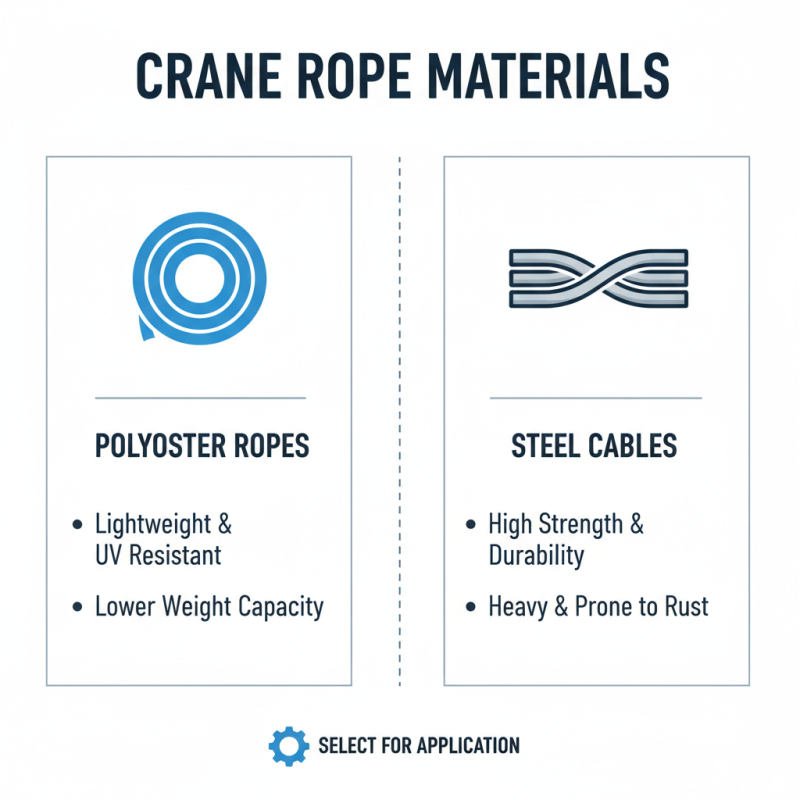

When selecting crane ceiling ropes, consider their load capacity and material. Steel cables are common due to their durability, but they are heavier and can be challenging to handle. Conversely, synthetic ropes are lighter and easier to manipulate but may not support the same weight. A report by the American Society of Mechanical Engineers (ASME) states that using the wrong type of rope can lead to increased risks of accidents. Many operators overlook this crucial aspect, leading to inadequate safety measures.

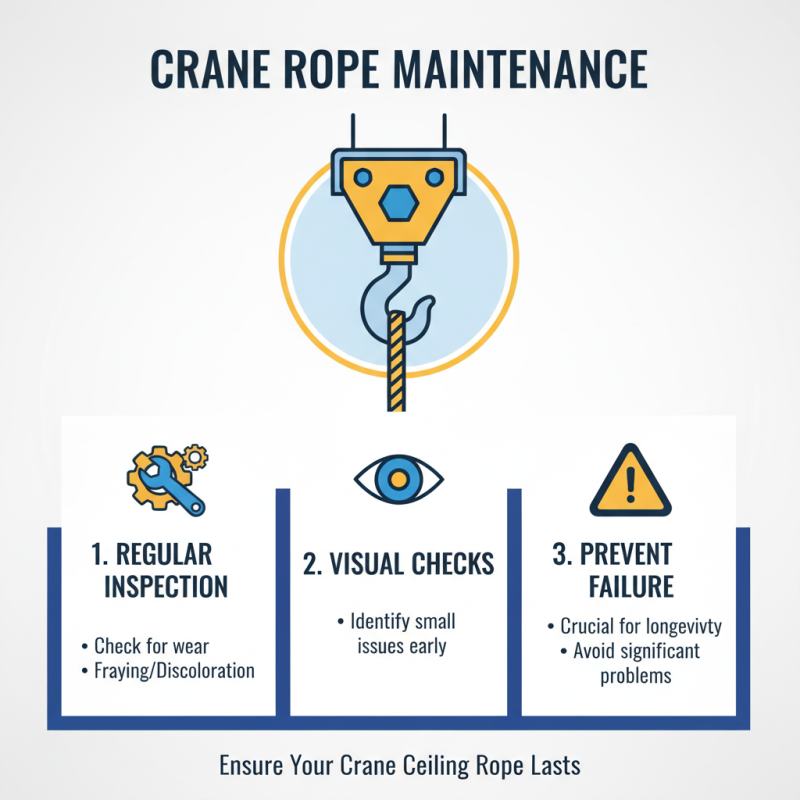

Additionally, maintenance of crane ceiling rope systems cannot be ignored. Regular inspections are vital. Reports indicate that over 30% of equipment failures result from poor maintenance. Signs of wear or fraying should never be ignored. It's crucial to stay informed about the latest safety guidelines and ensure your lifting apparatus functions as intended. This constant vigilance can significantly reduce the risk of accidents and enhance operational efficiency.

When selecting a crane ceiling rope, several key factors come into play. First, the lifting capacity is crucial. Many industry reports suggest that choosing a rope with a safety factor of at least 5:1 is essential. For instance, if you need to lift 1,000 pounds, a rope should support at least 5,000 pounds to ensure safety and reliability. This consideration can help avoid potential accidents during operation.

Material choice also influences performance. Common options include polyester, nylon, and polypropylene. Polyester ropes show superior abrasion resistance, which is vital in high-friction environments. A study found that ropes made with polyester can last up to 50% longer than those made from other materials under similar conditions.

Finally, the rope's diameter matters. Thicker ropes may offer better tensile strength but can be cumbersome. Conversely, thinner ropes may be lighter but can sacrifice durability. Finding the right balance is not always straightforward. Many operators struggle with these decisions, leading to potential pitfalls. Testing various ropes under your specific conditions can provide valuable insights, though it requires time and resources.

| Rope Type | Material | Weight Capacity | Length | Diameter | Special Features |

|---|---|---|---|---|---|

| Synthetic Rope | Nylon | 2000 lbs | 50 ft | 1/4 in | Lightweight, Weather-resistant |

| Wire Rope | Steel | 3000 lbs | 100 ft | 3/16 in | Durable, High tensile strength |

| Polyester Rope | Polyester | 1500 lbs | 75 ft | 3/8 in | UV resistant, Low stretch |

| Natural Fiber Rope | Manila | 1000 lbs | 60 ft | 5/8 in | Eco-friendly, Aesthetic appeal |

| Dyneema Rope | Dyneema | 4000 lbs | 30 ft | 1/8 in | Super lightweight, High strength |

| Polypropylene Rope | Polypropylene | 1200 lbs | 40 ft | 1/4 in | Buoyant, Resistant to abrasion |

| Kevlar Rope | Kevlar | 5000 lbs | 20 ft | 1/8 in | Heat resistant, High cut resistance |

| Braid-on-Braid Rope | Polyester | 2500 lbs | 65 ft | 1/4 in | Flexible, Great for lifting |

| Double Braid Rope | Nylon | 3000 lbs | 80 ft | 3/8 in | Strong, Excellent grip |

| Static Rope | Polyester | 1500 lbs | 70 ft | 5/16 in | Low stretch, Safety certification |

When selecting crane ceiling ropes, efficiency and durability are paramount.

According to industry reports, the right rope can enhance safety and performance in lifting operations.

The tensile strength and resilience of a crane ceiling rope determine its ability to handle heavy loads without failure.

A well-chosen rope can sustain up to 30% more weight than its rating, reducing operational risks.

Understanding the materials is crucial.

Synthetic ropes offer flexibility and resistance to environmental factors, while steel cables provide unparalleled strength.

This combination allows for a variety of uses across different industries. However, many users overlook the maintenance aspect.

Regular inspections for wear and tear can prevent accidents caused by fatigue.

Tips:

Always choose a rope that fits your specific needs. Check the manufacturer’s specifications for weight limits and reliability.

Educate your team on the importance of rope care.

Remember, a minor oversight can lead to significant problems in lifting operations.

Keep records of usage and maintenance. Continuous learning is vital in this field.

Don’t ignore the details; they can save lives.

When selecting crane ceiling ropes, the material choice is critical. Different materials have unique characteristics that affect durability and weight capacity. Polyester ropes, for instance, are lightweight and resist UV damage. Yet, they may not withstand heavy loads for long periods. In contrast, steel cables provide exceptional strength. These cables can handle heavy lifting, yet they come with drawbacks. They may rust over time and are heavier to manage.

Nylon ropes offer versatility. They have good elasticity, making them suitable for dynamic lifting applications. However, their lower tensile strength means they are not ideal for extremely heavy loads. A comparative analysis from industry experts suggests that while synthetic ropes are gaining popularity, steel cables are still the gold standard in demanding environments.

**Tips**: Choose rope material based on specific lifting requirements. Evaluate the environment where the ropes will be used. This can help in selecting the best option. Regular inspections are crucial. Look for signs of wear or damage. It’s a simple step, but it can prevent accidents. A proactive approach is key to ensuring safety and efficiency.

To ensure your crane ceiling rope lasts, maintenance is crucial. Regularly inspect the rope for signs of wear, such as fraying or discoloration. Visual checks are essential; small issues can lead to significant failures.

Tips: Keep the rope clean. Dirt and debris can weaken the fibers. Use a gentle soap and water solution for cleaning. Avoid using harsh chemicals that can damage the rope material.

Lubrication also matters. A light application of appropriate lubricant can safeguard against friction and wear. However, avoid over-lubricating as it may attract dirt and grime. Store the rope properly when not in use. Aim for a dry, cool environment away from direct sunlight.

Don’t forget to assess the load limits. Pushing the rope beyond its capacity is a frequent mistake. Make sure to always understand the limits to maintain safety and functionality. Sometimes, it’s easy to overlook these details. Keeping a maintenance log can help track inspection dates and wear levels.