Leave Your Message

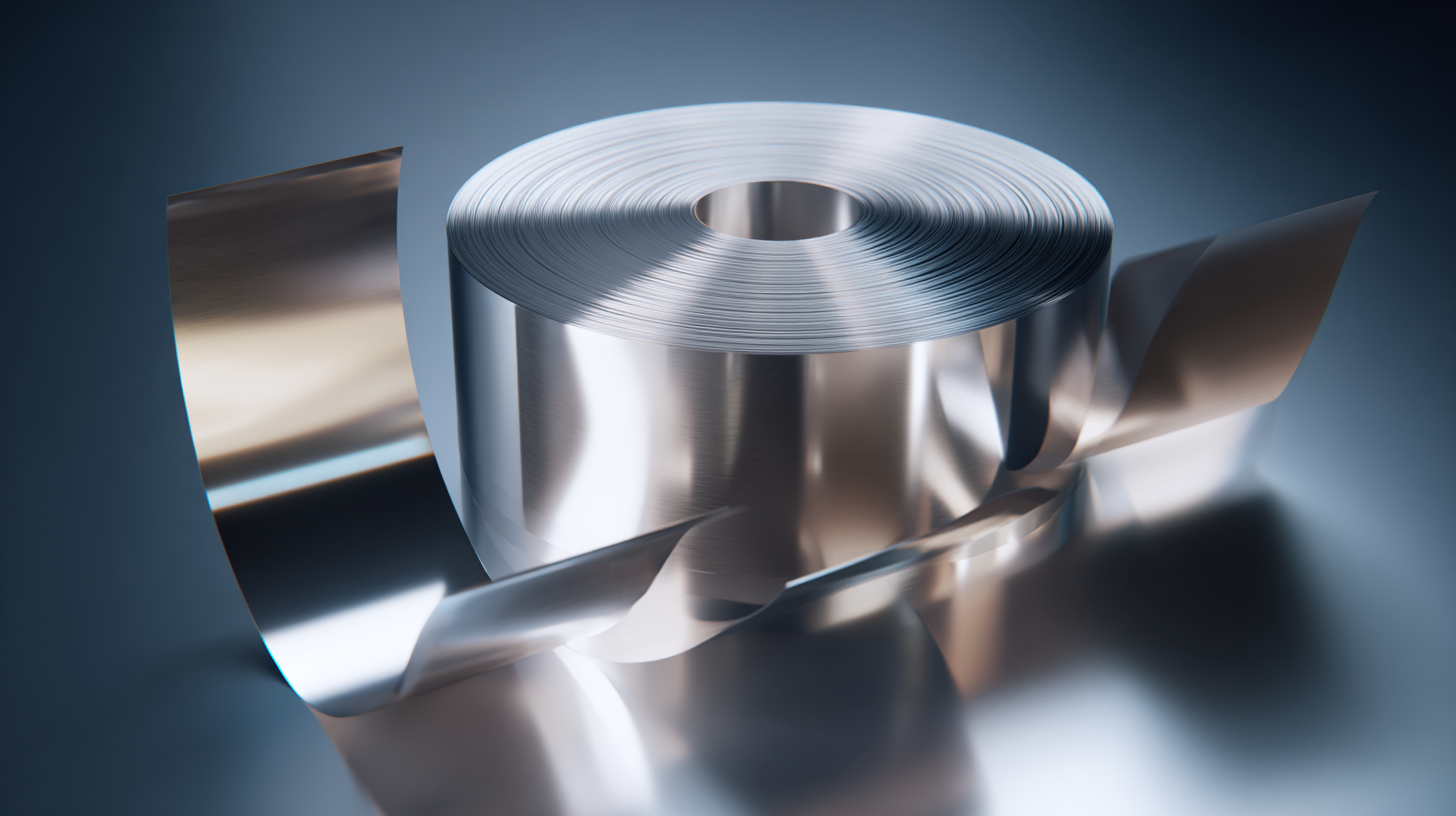

When it comes to selecting the right materials for industrial applications, the choice of a 304 Stainless Steel Belt is pivotal. This alloy, known for its excellent corrosion resistance and durability, is widely utilized across various sectors, including food processing, pharmaceuticals, and manufacturing. According to a report by the Global Stainless Steel Belt Market Research, the demand for 304 Stainless Steel Belts is projected to grow significantly, driven by the increasing need for high-quality, hygienic, and resilient materials in aggressive environments.

The properties of the 304 Stainless Steel Belt make it ideal for applications where both strength and flexibility are required. Its non-corrosive nature ensures longevity, which not only reduces replacement costs but also minimizes downtime in production processes. Furthermore, industry reports have highlighted that the adoption of stainless steel materials in conveyor systems is rising steadily, making it essential for businesses to understand how to choose the best belt tailored to their specific needs.

As industries evolve, understanding the nuances of selecting a 304 Stainless Steel Belt becomes crucial. The combination of its attributes—robust mechanical properties, resistance to oxidation, and ease of cleaning—positions it as a preferred choice for modern manufacturing solutions. This article aims to provide insights into choosing the ideal 304 Stainless Steel Belt that aligns with your operational requirements, ensuring both functionality and efficiency in your applications.

304 stainless steel is a versatile and widely used material known for its excellent corrosion resistance, durability, and aesthetic appeal. This alloy contains chromium and nickel, which contribute to its remarkable resistance to oxidation and a variety of corrosive environments, making it an ideal choice for applications ranging from kitchen appliances to industrial equipment. The key properties of 304 stainless steel also include good weldability and formability, allowing for easy fabrication into various shapes and designs.

304 stainless steel is a versatile and widely used material known for its excellent corrosion resistance, durability, and aesthetic appeal. This alloy contains chromium and nickel, which contribute to its remarkable resistance to oxidation and a variety of corrosive environments, making it an ideal choice for applications ranging from kitchen appliances to industrial equipment. The key properties of 304 stainless steel also include good weldability and formability, allowing for easy fabrication into various shapes and designs.

When selecting the best 304 stainless steel belt for your needs, consider the specific application and environmental conditions. For instance, if the belt will be exposed to high heat or harsh chemicals, look for grades that offer enhanced resistance to those factors.

Tips: Always check the belt specifications for load capacity and surface finish, as these can greatly affect performance. Additionally, consult with suppliers to ensure you're choosing the right thickness and length for your project, as these factors can influence both functionality and durability. By understanding the properties and advantages of 304 stainless steel, you can make an informed decision tailored to your unique requirements.

When it comes to selecting a 304 stainless steel belt, understanding your specific needs is crucial. The 304 stainless steel grade is renowned for its versatility and excellent corrosion resistance, making it a preferred choice in various industries, including food processing, pharmaceuticals, and chemical manufacturing. According to a recent report by the Stainless Steel Development Association, approximately 70% of stainless steel used in industrial applications is of the 304 grade, thanks to its balance of strength and workability.

Identifying the application for which you require a stainless steel belt is essential. For example, in the food industry, hygiene and corrosion resistance are paramount, which is where 304 stainless steel excels. It can withstand harsh cleaning agents and high temperatures, making it ideal for conveyor belts in bakeries and meat processing facilities. On the other hand, if the application involves exposure to aggressive chemicals, one might need to consider alternative grades or coatings. The International Stainless Steel Forum highlights that choosing the right grade not only enhances performance but also extends the lifespan of the equipment, reducing long-term operational costs.

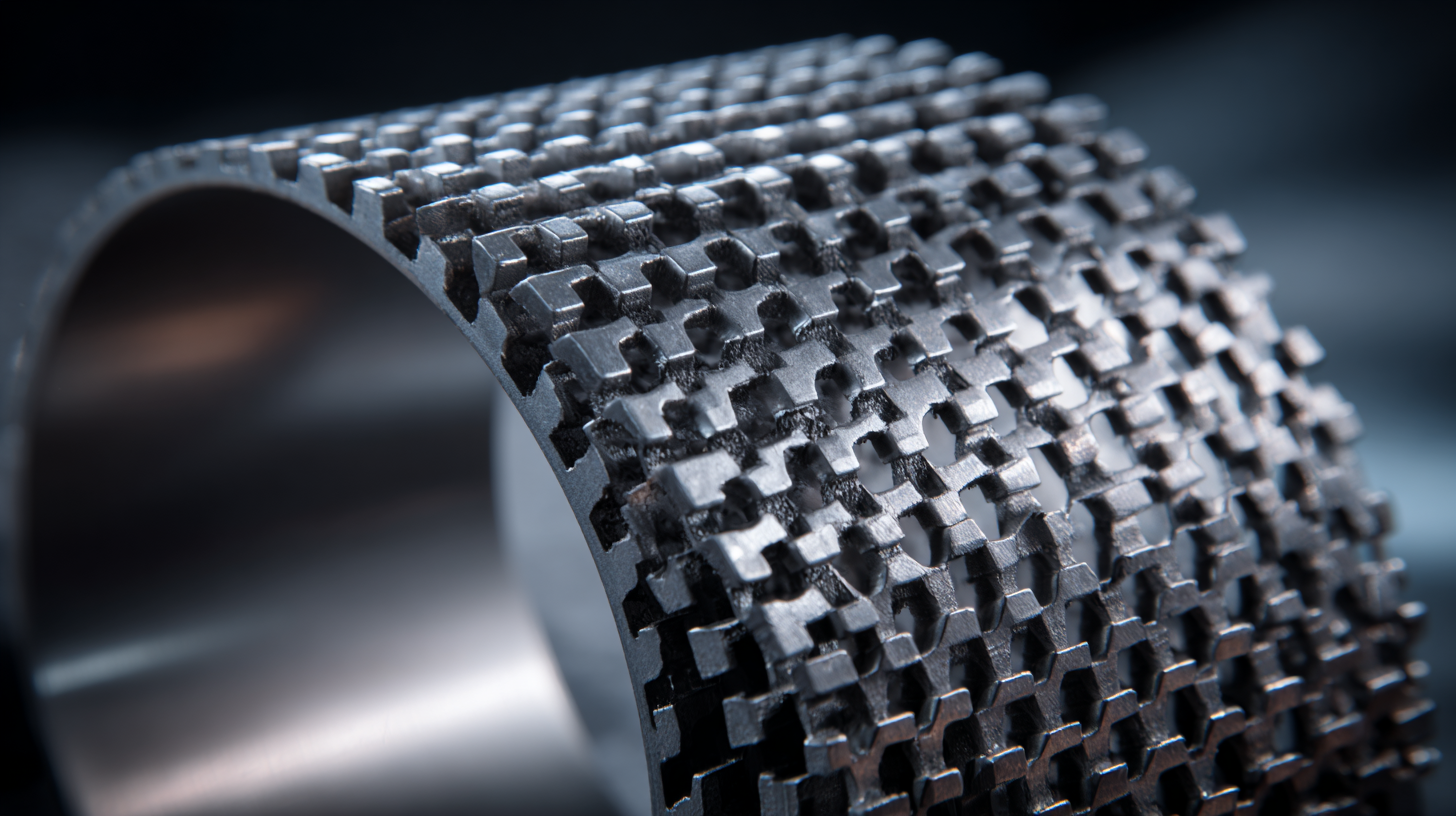

When selecting the best 304 stainless steel belt for your needs, quality assessment is paramount. Begin by examining the belt's thickness and weave density; a thicker belt often offers improved durability and longevity. Additionally, the density of the weave plays a critical role in the strength and weight capacity of the belt. Look for a higher density weave if you expect to transport heavier materials, as this can significantly enhance performance.

Another vital factor to consider is the surface finish of the belt. A smooth, polished finish not only provides a sleek appearance but also aids in resistance to corrosion and rust, which are common concerns with stainless steel products. Furthermore, ensure that the stainless steel used is of genuine 304 grade, known for its excellent resistance to oxidation and a balanced composition of chromium and nickel. Always request certifications or material test reports from suppliers to verify the quality of the stainless steel components in your belt.

| Feature | Description | Importance |

|---|---|---|

| Material Grade | 304 stainless steel is corrosion-resistant and ideal for various applications. | High |

| Thickness | A thicker belt offers more durability and better load-bearing capacity. | Moderate |

| Finish Type | Polished finishes reduce friction and provide aesthetic appeal. | Moderate |

| Temper | Different temper conditions affect hardness and flexibility. | High |

| Width Options | Various widths to suit specific machinery requirements. | High |

| Weight Capacity | Ensure the belt meets or exceeds your load requirements. | Very High |

| Temperature Resistance | Ability to withstand high temperatures necessary for specific applications. | High |

| Ease of Installation | Consider if the belt can be easily installed and maintained. | Moderate |

When selecting between 304 stainless steel and other stainless steel alloys, understanding their distinct properties is crucial for making an informed decision. The 304 grade is renowned for its excellent corrosion resistance and mechanical properties, making it versatile for various applications, from kitchenware to industrial components. The influence of factors such as surface quality can significantly affect the corrosion resistance of 304 stainless steel, particularly in corrosive environments, such as those with high chloride levels. Comparatively, alloys like 316 offer enhanced resistance to pitting and crevice corrosion, thanks to increased molybdenum content, making them suitable for more aggressive conditions.

Moreover, pricing trends can impact purchasing decisions, as the market dynamics of stainless steel are influenced by extra-alloy components that affect overall costs. As industries scale their operations, guidance prices set by domestic large stainless steel mills can create ripple effects across different markets. Understanding these correlations, along with the performance characteristics of each alloy, is paramount for ensuring that the chosen material aligns with specific operational needs while maintaining budgetary constraints. Thus, carefully assessing the unique features of 304 stainless steel in comparison to alternatives can lead to better procurement strategies tailored to individual requirements.

When selecting the best 304 stainless steel belt for your needs, budget considerations play a crucial role. The price of these belts can vary widely based on quality, thickness, and additional features. Understanding your budget should guide your decision-making process, ensuring you find a belt that meets both your requirements and financial limits.

Tips: Before making a purchase, compare prices from multiple suppliers to ensure you're getting the best deal. Look for discounts or bulk purchase options, as many suppliers may offer lower prices for larger orders. Additionally, consider the long-term cost: investing in a higher-quality belt may save you money in the long run by reducing the need for frequent replacements.

It's also essential to assess the specific features you need. Are you looking for corrosion resistance, durability, or flexibility? Identifying the essential qualities will help you narrow down options that fit within your budget. Don't hesitate to reach out to manufacturers for quotations and inquire about warranty options that could provide added value to your investment.