Leave Your Message

Choosing the right 316l Stainless Steel Belt can significantly impact your projects. This material is known for its corrosion resistance and durability. Industry expert Dr. Jennifer Hawthorne once noted, "Selecting the right belt is crucial for performance and longevity."

When considering a 316l Stainless Steel Belt, you need to assess your specific requirements. Different applications have unique demands. Think about factors like environment, load capacity, and tension. It's easy to overlook these elements. However, each choice shapes your experience.

Understanding the nuances of 316l Stainless Steel can be challenging. The market offers various options, each with distinct features. Look for belts that match your needs but don't rush the process. Take your time, and consult professionals to avoid costly mistakes. Even a small oversight can lead to setbacks.

316L stainless steel is widely known for its superb corrosion resistance and strength. This alloy contains a low carbon content, which enhances its ability to withstand harsh environments. According to recent data, it can resist corrosion in a variety of settings, including marine and chlorinated environments. This makes it a popular choice in industries such as food processing and pharmaceuticals.

The properties of 316L also contribute to its versatility. It has high tensile strength and excellent weldability. However, one should consider that extreme temperatures can affect its mechanical properties. Reports indicate that while it performs well under moderate heat, prolonged exposure to high temperatures may lead to reduced strength. Thus, careful consideration of application conditions is essential.

Moreover, while 316L offers great advantages, cost can be a limiting factor. This alloy tends to be more expensive than other stainless steels. Users should weigh the benefits against the budget constraints. For those requiring high performance and durability, the investment is often justifiable. Yet, it is crucial to assess whether the added benefits align with specific needs.

This chart illustrates the key properties of 316L stainless steel, highlighting its high corrosion and temperature resistance, along with decent tensile strength, ductility, and weldability. These characteristics make 316L an ideal choice for various applications in demanding environments.

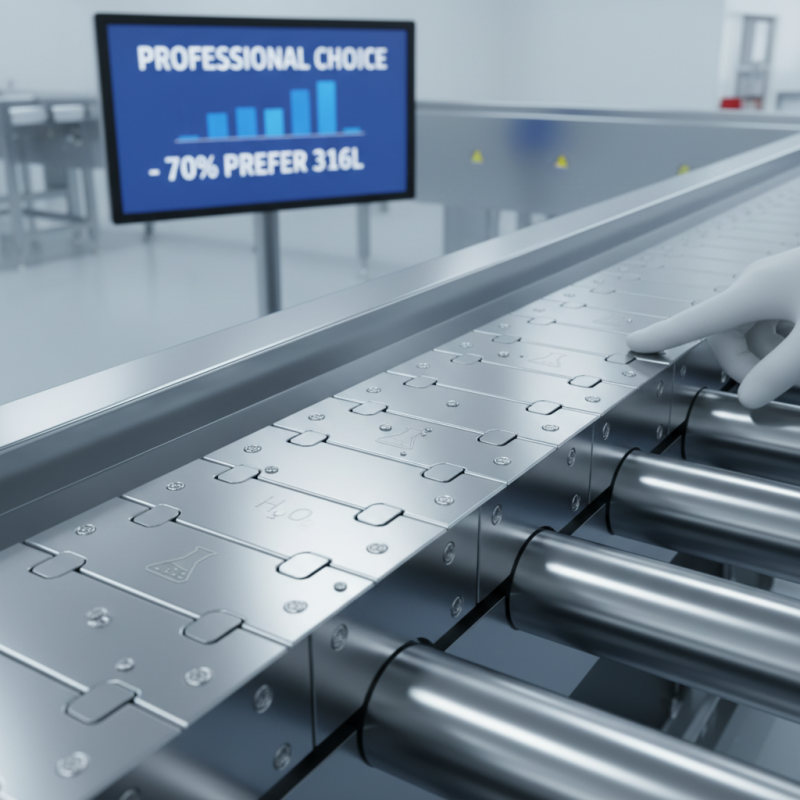

When selecting a stainless steel belt, identifying your specific needs is crucial. The 316L grade is known for its corrosion resistance. This makes it ideal for environments with moisture and chemicals. According to the latest industry report, 70% of professionals prefer this material for its durability. Yet, are you considering the specific conditions where your belt will be used?

Assess the load capacity and the dimensions of your application. Many users overlook these factors, leading to underperformance. A typical width varies from 1 inch to 6 inches, affecting the overall strength. The wrong choice might warp or break under pressure. Additionally, your needs might involve conveyors in food processing. Here, hygiene standards are paramount. A report indicates that 85% of stainless steel belts meet FDA regulations. But, are they truly designed for easy cleaning?

Lastly, think about mobility and flexibility. Not all belts are built for ease of movement. Some may bend too much, causing jams. Various specifications exist, and understanding the nuances can save time and money. Each decision carries weight—choose wisely for efficiency and safety.

Choosing the right 316L stainless steel belt involves several critical factors. The belt's grade is important. 316L is known for its corrosion resistance, making it ideal for harsh environments. Consider the width and thickness of the belt. A wider belt can distribute weight better, while thickness affects durability and flexibility.

It's also essential to assess the manufacturing process. Some belts may have imperfections. Inspecting these details can save you trouble later. Pay attention to the buckle type as well. A secure connection is crucial for safety and functionality. You want a belt that holds up under pressure, not one that frays or breaks easily.

Material quality matters too. Not all 316L stainless steel is equal. Lower quality options may corrode and weaken faster. Think about the intended use. Will it be for industrial applications or casual wear? Each use requires different features. Reflect on these aspects carefully, and you’ll find a belt that fits your specific needs.

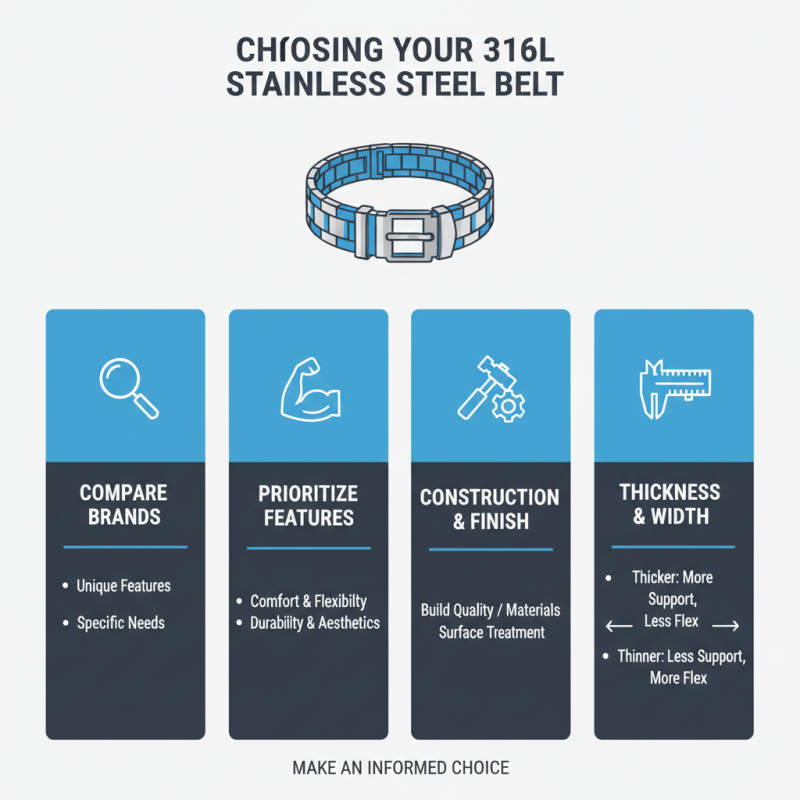

When choosing a 316L stainless steel belt, it's crucial to compare various brands available in the market. Each brand offers unique features that may or may not meet your specific needs. Some belts prioritize comfort and flexibility, while others focus on durability and aesthetics. Investigate their construction and finish. Pay attention to the thickness and width of the belts. A thicker belt might provide more support but could be less flexible during movement.

In the market, options vary widely. Some brands emphasize high corrosion resistance, perfect for humid environments. Others highlight designs that are stylish yet practical. Look for detailed specifications, including tensile strength and wear resistance. It's vital to understand that a visually appealing product might not necessarily perform well. Reviews from users can offer real insights, but they may reflect personal preferences. Check for common feedback regarding discomfort or adaptability. This can guide you toward making a more informed decision.

Proper maintenance of a 316L stainless steel belt is crucial for its longevity. Regular cleaning helps prevent build-up of debris and contaminants. Use mild soap and water for daily cleaning. Avoid harsh chemicals; these can damage the surface. After cleaning, ensure the belt is thoroughly dried. Leaving it wet can lead to rust and other issues.

Inspect the belt regularly for scratches or wear. Small scratches can become larger if ignored. Store your belt in a dry, cool area to minimize exposure to moisture. This is often neglected but is key to preventing corrosion. If you notice any signs of damage, consider seeking professional help. Repairs may extend the life of your belt significantly.

Maintaining proper tension is another aspect that can be overlooked. An overly tight belt can lead to mechanical issues. On the flip side, a loose one may not function effectively. Regularly check the tension and adjust as necessary. Thoughtful attention to these details can make a big difference.

| Attribute | Details |

|---|---|

| Material Type | 316L Stainless Steel |

| Corrosion Resistance | High (excellent in chloride environments) |

| Temperature Range | -200°C to 900°C |

| Belt Width Options | Varies from 10mm to 1000mm |

| Common Applications | Food processing, pharmaceuticals, and petrochemicals |

| Maintenance Tips | Regular cleaning, avoid abrasive materials, inspect for wear |

| Lifespan | 5 to 15 years depending on usage and maintenance |