Leave Your Message

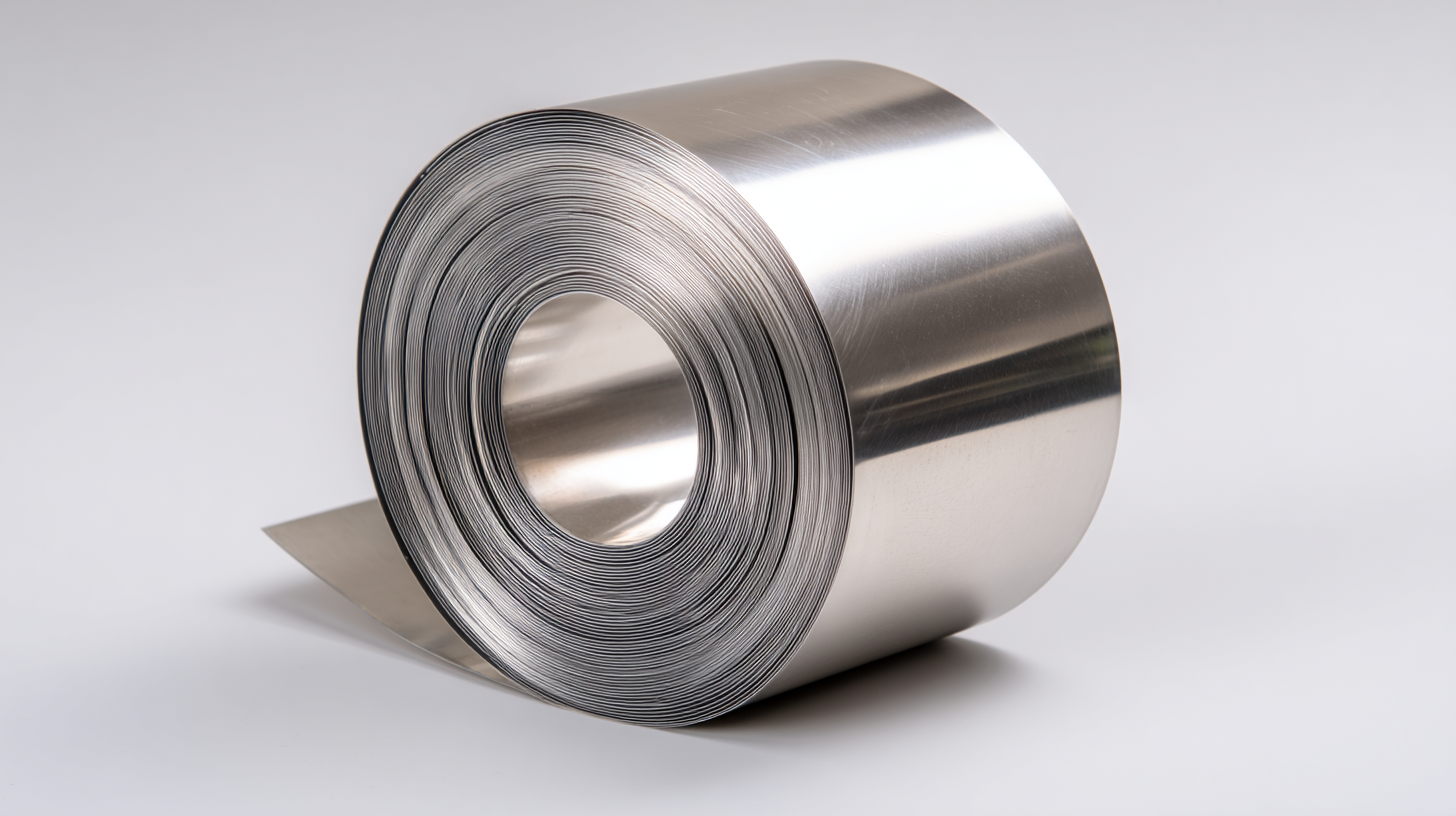

Choosing the right 304 Stainless Steel Belt for your industrial applications can significantly impact efficiency, durability, and overall operational success. This high-quality material is renowned for its excellent corrosion resistance, strength, and versatility, making it a popular choice across various industries such as food processing, packaging, and manufacturing. However, with the myriad of options available, selecting the most suitable 304 Stainless Steel Belt may seem daunting. Understanding the specific requirements of your operations, including the environment in which the belt will be used, the load capacity, and the necessary hygienic standards, is crucial for making an informed decision. This guide will provide you with essential insights and practical tips to navigate the selection process, ensuring you find the perfect 304 Stainless Steel Belt tailored to your unique industrial needs.

When selecting the right 304 stainless steel belt for industrial applications, understanding its properties is paramount.

304 stainless steel is renowned for its excellent corrosion resistance and good mechanical properties, making it suitable for a wide range of environments, including those exposed to extreme temperatures.

This type of stainless steel is also known for its ease of fabrication and formability, which is essential in industries requiring complex component shapes.

The material's strength and durability further contribute to its popularity across various sectors, such as construction, automotive, and energy.

Tips: When choosing a 304 stainless steel belt, consider the specific environmental conditions it will face. For example, in applications exposed to harsh chemicals or high humidity, ensure that the steel's corrosion resistance is suited for such challenges.

Additionally, examine the thickness and width of the belt to ensure it can withstand the mechanical stresses of your operation without compromising performance.

Tips: When choosing a 304 stainless steel belt, consider the specific environmental conditions it will face. For example, in applications exposed to harsh chemicals or high humidity, ensure that the steel's corrosion resistance is suited for such challenges.

Additionally, examine the thickness and width of the belt to ensure it can withstand the mechanical stresses of your operation without compromising performance.

Ensure that any product you select meets industry standards and specifications. Consulting with suppliers or manufacturers can provide insights into certifications and quality assurance, ultimately supporting your decision in selecting the right 304 stainless steel belt tailored for your precise industrial needs.

When selecting the right 304 stainless steel belt for industrial applications, several key factors must be taken into account. First, the environment in which the belt will be used is crucial. Consideration of temperature extremes, exposure to corrosive substances, and the presence of abrasive materials can significantly influence the choice of stainless steel grade and belt construction. The durability and resistance to chemical damage will determine the longevity and performance of the belt in the intended application.

Another important factor is the belt's load-bearing capacity. It is essential to assess the weight and type of materials that will be transported on the belt to ensure it can handle operational demands. Additionally, belt width, thickness, and overall design should align with machinery specifications and the workflow requirements of the facility. Ensuring compatibility with conveyor systems and ease of installation will also contribute to a smoother operational process. By thoroughly evaluating these criteria, businesses can make well-informed decisions that enhance productivity and efficiency in their industrial operations.

When selecting a 304 stainless steel belt for your industrial needs, it's crucial to evaluate the performance requirements specific to your environment. Factors such as temperature, humidity, and exposure to corrosive substances can significantly impact the belt's performance and longevity. For instance, if your operation involves high temperatures, ensure the belt can withstand such conditions without compromising its integrity.

**Tips:** Consider assembling a checklist of environmental conditions that your belt will encounter. This could include maximum and minimum temperatures, potential chemical exposures, and the mechanical load it will need to support.

Additionally, ensure that the chosen belt aligns with the intended application, whether it's for food processing, packaging, or material handling. Each application may have different specifications regarding thickness, width, and surface finish.

**Tips:** Compare different manufacturers and their offerings to ensure you are getting a belt that meets your specific standards. Don’t hesitate to ask for performance data or certification documents to make a well-informed decision.

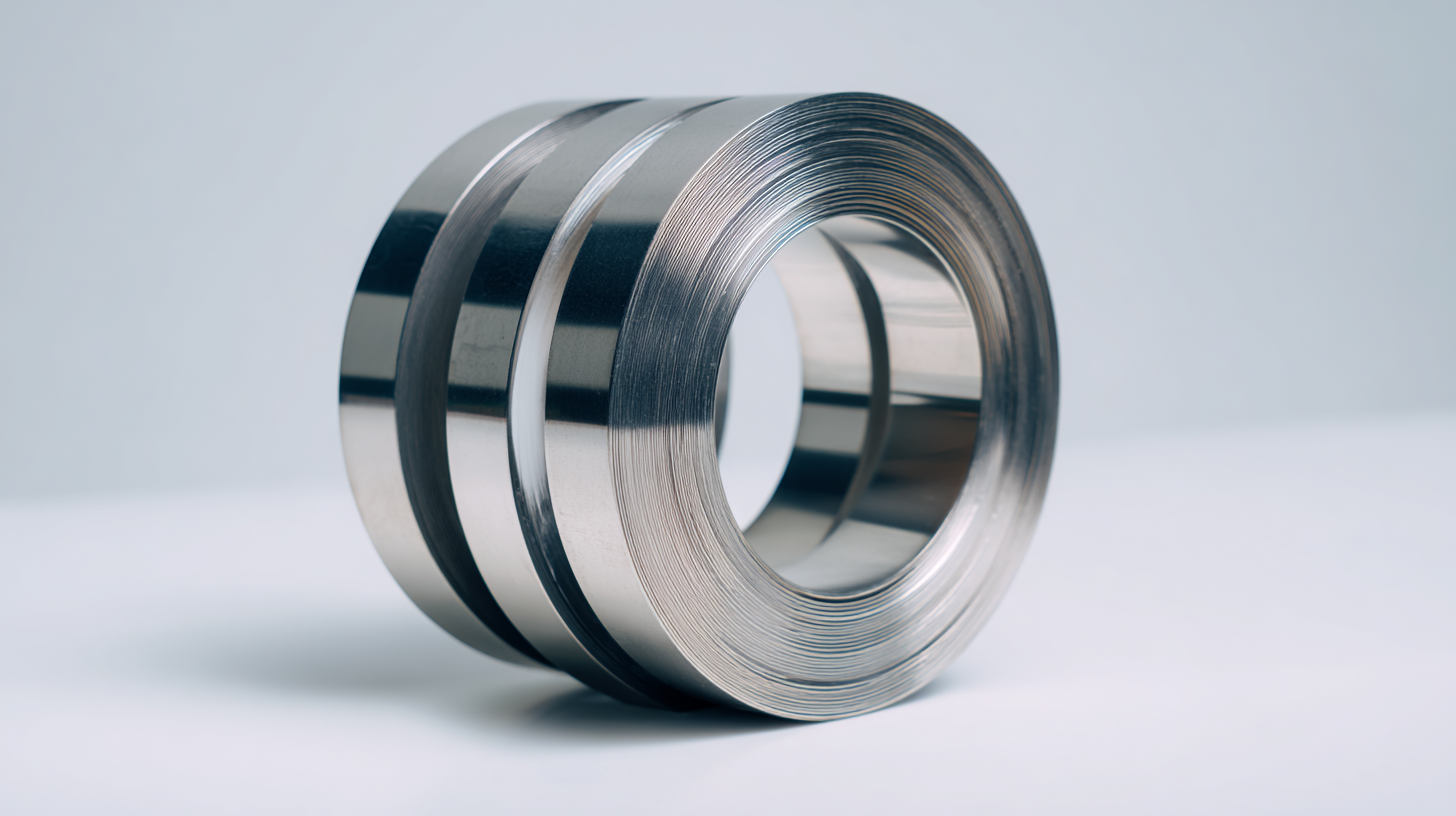

When selecting a 304 stainless steel belt for industrial applications, it's essential to compare the various types available in the market. The most common types include

flat belts, modular belts, and timing belts, each designed to cater to specific operational requirements.

According to the International Stainless Steel Forum (ISSF), 304 stainless steel is renowned for its excellent corrosion resistance and strength, making it suitable for

food processing, pharmaceuticals, and chemical handling.

Flat belts, often used in conveyor systems, are ideal for transporting bulk materials. The versatility of modular belts

allows for easy maintenance and replacement, particularly in environments with frequent cleaning cycles, such as meat processing plants.

Timing belts, on the other hand, offer precise movement and are crucial in applications requiring synchronization, such as bottling lines. A report from Grand View Research states that

the industrial belts market is projected to reach USD 12 billion by 2026, highlighting the growing demand for durable and efficient solutions in various industries.

Understanding these differences can aid in making a well-informed choice tailored to specific industrial needs.

Maintaining the longevity of stainless steel belts in industrial operations is crucial to ensure smooth and efficient workflow. Regular inspection is the cornerstone of effective maintenance. Operators should routinely examine belts for signs of wear, such as cracks, corrosion, or abnormal elongation. Identifying these issues early can prevent costly downtime and interruptions in production. Additionally, proper cleaning is essential to remove contaminants like grease, dust, and debris that can cause wear over time. Using mild detergents and warm water, along with non-abrasive cleaning tools, will help preserve the belt's integrity.

Lubrication is another critical aspect of maintaining stainless steel belts. While these belts are designed to withstand harsh conditions, they benefit from being lubricated to reduce friction and heat buildup. It’s essential to use recommended lubricants that are compatible with stainless steel, ensuring they do not compromise the material's properties. Furthermore, proper alignment and tensioning of the belts will minimize stress during operation, extending their lifespan significantly. By following these maintenance tips, industrial facilities can enhance the durability and performance of their stainless steel belts, leading to more reliable operations.