Leave Your Message

The future of industrial operations hinges significantly on advancements in materials and equipment, particularly in the realm of heavy duty crane rope. According to a recent report by ResearchAndMarkets, the global crane market is expected to grow at a CAGR of 4.3% from 2021 to 2026, driven largely by the demand for increased efficiency and safety in heavy lift applications.

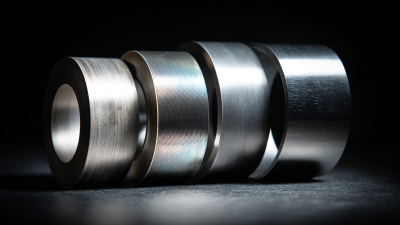

Heavy duty crane ropes are a vital component in this equation, as they not only support substantial loads but also enhance the performance and reliability of cranes in various industrial settings. Innovations in rope materials, such as the development of synthetic fibers and high-strength steel, promise to reduce weight while improving load capacity and durability.

As industries evolve and face the challenges of modern logistics, the integration of advanced heavy duty crane rope technology will play a crucial role in boosting operational efficiency and safety standards, driving the future landscape of heavy lifting operations.

The industrial sector is constantly evolving, and the innovations in crane rope materials play a crucial role in enhancing durability and efficiency. Recent studies indicate that shifting from traditional steel ropes to advanced synthetic materials, such as high-modulus polyethylene (HMPE), can increase the lifespan of crane ropes by up to 25%. These innovative materials not only reduce weight but also improve resistance to abrasion and environmental damage, thus ensuring a longer operational life under heavy-duty conditions.

The industrial sector is constantly evolving, and the innovations in crane rope materials play a crucial role in enhancing durability and efficiency. Recent studies indicate that shifting from traditional steel ropes to advanced synthetic materials, such as high-modulus polyethylene (HMPE), can increase the lifespan of crane ropes by up to 25%. These innovative materials not only reduce weight but also improve resistance to abrasion and environmental damage, thus ensuring a longer operational life under heavy-duty conditions.

Incorporating these advanced materials can significantly enhance productivity. For instance, cranes fitted with HMPE ropes experience reduced wear on pulleys, which can lead to lower maintenance costs and minimized downtime. As reported by the International Journal of Heavy Machinery and Applications, firms that have adopted these innovations have noted efficiency improvements of about 15% in their lifting operations.

Tip: When selecting crane ropes, consider factors such as load capacity, environmental conditions, and specific lifting requirements. This ensures the best match between the rope material and the operational demands.

Tip: Regularly inspecting crane ropes for signs of wear can help in early identification of potential failures. This proactive approach keeps operations running smoothly and reduces unexpected downtime.

The integration of smart technology in heavy-duty crane ropes marks a transformative shift in the industrial sector. As industries strive for higher efficiency and safety standards, the development of intelligent ropes equipped with sensors plays a pivotal role. These sensors monitor various parameters such as load weight, tension, and temperature in real time, allowing operators to make informed decisions and prevent potential failures before they occur. This proactive approach not only enhances operational reliability but also significantly reduces downtime associated with equipment failure.

Moreover, the data collected from these smart ropes can be analyzed to optimize performance and predict maintenance needs. With advanced analytics, companies can develop predictive models that help in scheduling maintenance based on actual usage rather than a rigid maintenance schedule. This innovation not only saves on maintenance costs but also extends the lifespan of both the crane and the rope, promoting sustainability in industrial operations. As industries look to the future, the fusion of smart technology and traditional heavy-duty crane ropes represents a leap forward in enhancing operational efficiency and safety.

As industries increasingly prioritize sustainability, the crane rope manufacturing sector is experiencing a transformation towards eco-friendly innovations. The global synthetic rope market, projected to grow from USD 1.77 billion in 2025 to USD 3.04 billion by 2033, indicates a burgeoning demand for sustainable materials in heavy-duty applications, with a compound annual growth rate (CAGR) of 7.04%. This growth is largely fueled by advancements in synthetic rope technologies, which not only improve durability and performance but also lessen environmental impacts compared to traditional materials.

Moreover, the integration of digital fabrication technologies—such as 3D printing and automated weaving—into the manufacturing process is reshaping the textiles and rope industries. These innovations contribute to more sustainable production methods, reducing waste and energy consumption. For instance, companies are actively exploring eco-friendly practices that emphasize the use of recyclable materials and energy-efficient processes. A recent report highlighted the sustainable manufacturing equipment market, which surpassed USD 244.3 billion in 2024 and is projected to grow further, demonstrating a collective shift toward responsible manufacturing practices across multiple sectors, including crane rope production.

This chart illustrates the percentage of different eco-friendly innovations in crane rope manufacturing that contribute to overall industrial efficiency. The innovations selected are based on their growing importance in sustainability efforts within the industry.

In the ever-evolving landscape of industrial operations, the safety enhancements offered by modern crane ropes play a pivotal role in improving workplace efficiency. Innovations in crane rope technology not only bolster operational capabilities but also prioritize worker safety. Advanced materials and designs have led to ropes that are lighter yet stronger, reducing the risk of accidents caused by equipment failure. These upgrades allow for smoother, more controlled lifting operations, minimizing potential hazards associated with heavy loads.

Moreover, enhancing safety through improved crane ropes directly contributes to a more productive environment. When workers can trust their equipment, they are more likely to perform tasks with confidence and focus, reducing stress and increasing job satisfaction. Companies that invest in these safety-conscious technologies can witness significant returns, including reduced absenteeism and lower healthcare costs. Ultimately, the integration of modern crane rope innovations reflects a commitment not only to operational excellence but also to the well-being of employees, fostering a culture of safety that translates into overall organizational success.

| Rope Type | Material | Load Capacity (tons) | Safety Factor | Lifespan (Years) | Innovative Features |

|---|---|---|---|---|---|

| Wire Rope | Steel | 50 | 5:1 | 10 | Corrosion-resistant coating |

| Synthetic Rope | Polypropylene | 20 | 6:1 | 15 | Lightweight and low stretch |

| Fiber Rope | Nylon | 15 | 7:1 | 12 | UV resistance and improved grip |

| Hybrid Rope | Steel + Synthetic | 30 | 8:1 | 20 | Enhanced durability with flexibility |

| High-Performance Rope | Dyneema | 25 | 10:1 | 18 | High strength-to-weight ratio |

As industries evolve, so do the tools that support them. In the realm of heavy-duty cranes, rope design is undergoing a significant transformation driven by the need for enhanced efficiency and safety. The future trends indicate a shift towards materials that are not only lighter but also stronger and more resilient. Innovations like synthetic ropes engineered with advanced polymers are being explored, offering superior tensile strength while reducing weight. This paradigm shift allows for increased lifting capacities and improved handling, which is critical for heavy-duty operations.

Furthermore, the integration of smart technology within crane rope design is on the horizon. Sensors embedded in crane ropes could provide real-time data on wear and tear, allowing operators to make informed decisions about maintenance and replacement. This predictive maintenance model not only enhances safety by preventing accidents related to equipment failure but also optimizes operational efficiency. As industries continue to prioritize sustainability, future crane ropes may also incorporate eco-friendly materials and production processes, aligning with global efforts to reduce carbon footprints.