Leave Your Message

The innovative applications of 316 Stainless Steel Channel in modern construction and design techniques are transforming the industry, offering enhanced durability and aesthetic appeal. According to a report by the International Stainless Steel Forum, the global demand for stainless steel is projected to grow by 2.5% annually, with 316 stainless steel being favored for its exceptional corrosion resistance and strength in harsh environments. The versatile design of 316 Stainless Steel Channel allows architects and engineers to explore new structural forms while maintaining performance standards. As sustainable building practices gain traction, the recyclability and longevity of stainless steel components reinforce their appeal, aligning with the industry’s shift toward eco-friendly materials. This integration of advanced materials not only meets the rigorous demands of modern infrastructure but also complements innovative design approaches aimed at enhancing overall user experience and functionality.

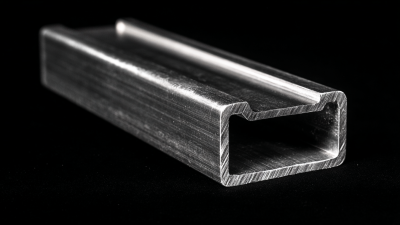

The 316 stainless steel channel is increasingly recognized in modern construction and design for its exceptional corrosion resistance and longevity. According to a report by the International Stainless Steel Forum, 316 stainless steel has a higher resistance to corrosion compared to 304 stainless steel due to the presence of molybdenum, which provides increased protection against chlorides and harsh environmental conditions. This characteristic makes it an ideal choice for coastal constructions and other applications exposed to corrosive substances.

In terms of longevity, studies indicate that structures utilizing 316 stainless steel can potentially extend their lifespan by up to 50 years with minimal maintenance. The durability of this material significantly reduces the need for frequent replacements or repairs, which not only saves costs over time but also contributes to sustainability by minimizing waste. The enhanced longevity and low maintenance requirements make the 316 stainless steel channel a compelling option for modern architects and builders seeking reliable and aesthetically pleasing solutions in their projects.

The architectural landscape is rapidly evolving, and one of the standout materials shaping this transformation is the 316 stainless steel channel. Renowned for its durability and resistance to corrosion, particularly in urban environments, this material is increasingly being employed in innovative facade designs. According to a recent report by Grand View Research, the global stainless steel market is projected to reach $160 billion by 2025, with a considerable portion attributed to construction applications. The versatility of 316 stainless steel allows architects to create striking aesthetic elements without compromising on strength or longevity.

In modern architectural practices, 316 stainless steel channel is utilized not only for structural purposes but also as an eye-catching design feature. Its reflective surface can enhance natural light, creating dynamic visual effects across building facades. The American Institute of Architects has noted a trend towards using metal facades, with reports indicating that about 35% of commercial buildings now feature metal cladding systems. This shift highlights the growing appreciation for materials that offer both functional and creative benefits, where 316 stainless steel channels stand out by providing both a modern aesthetic and the resilience required for enduring designs.

The use of 316 stainless steel channel in modern construction has emerged as a pivotal innovation for structural support solutions. Renowned for its excellent corrosion resistance and strength, 316 stainless steel is particularly effective in marine environments and applications exposed to harsh chemicals. According to the Stainless Steel Institute, 316 stainless steel demonstrates superior integrity with a tensile strength of over 70,000 psi, making it an ideal choice for structural applications requiring durability and longevity.

In contemporary design, architects and engineers are increasingly leveraging 316 stainless steel channels to create sleek and resilient frameworks. For instance, recent studies indicate that incorporating stainless steel channels can reduce maintenance costs by up to 30% compared to traditional materials, thereby enhancing the lifecycle of constructions. In high-traffic and industrial areas, the aesthetic versatility and structural efficiency of 316 stainless steel channels facilitate innovative designs while meeting stringent building codes. The rising demand for sustainable materials further supports the transition towards stainless steel, as it is fully recyclable and contributes to greener building practices.

The use of 316 stainless steel channel in modern construction not only enhances structural integrity but also aligns with sustainable design practices. With its excellent corrosion resistance and durability, 316 stainless steel contributes to longer lifespans for buildings, reducing the need for frequent replacements and maintenance. According to a report by the U.S. National Institute of Standards and Technology, using high-performance materials like 316 stainless steel can improve the lifecycle assessment of construction projects by up to 30%, highlighting its role in sustainable architecture.

In addition, the recyclability of stainless steel is a significant advantage. The World Stainless Steel Association states that approximately 90% of stainless steel is recycled at the end of its life, making it an environmentally friendly choice. Incorporating 316 stainless steel channels into construction allows architects and builders to achieve design flexibility while promoting resource efficiency. This synergy of aesthetics and sustainability exemplifies the innovative approaches adopted by modern designers, demonstrating that cutting-edge techniques can lead to eco-conscious constructions that are both functional and visually appealing.

The efficient fabrication and installation of 316 stainless steel channels have become increasingly vital in modern construction and design, particularly when leveraging advanced technologies. Recent developments in the combined electrochemical and mechanical polishing techniques have shown promising results in enhancing the internal surfaces of components produced through additive manufacturing. For instance, parts fabricated using metal additive manufacturing (MAM) without post-processing tend to fall short in high-performance applications due to suboptimal surface quality. Industry reports have indicated that post-processing techniques can significantly improve the structural integrity and performance metrics of these components.

In addition, innovative fabrication methods like micro-incremental forming (μ-ISF) have successfully produced serpentine micro-channels in SS 316 sheets. This technique has demonstrated the ability to maintain material integrity while achieving a depth of 0.7 mm, which opens up new frontiers in applications requiring complex fluid dynamics. Furthermore, the magnetically driven internal finishing of stainless steel components highlights a growing trend in achieving high-quality surface finishes suitable for industries such as aerospace and medical. As these methods evolve, they promise to enhance the overall efficiency and effectiveness of employing 316 stainless steel channels in various high-performance construction projects.