Leave Your Message

In the ever-evolving landscape of global supply chains, the choice of materials plays a critical role in ensuring product reliability and performance. Among the various options available, 316L stainless steel pipe has emerged as a favored choice among industries, thanks to its unique properties that enhance durability and resistance to corrosion. According to a recent report by Grand View Research, the global stainless steel pipe market is projected to reach approximately USD 16.5 billion by 2025, with 316L grades being a significant contributor due to their superior strength and resistance to pitting in chloride environments. This remarkable material not only meets stringent industry standards but also addresses the increasing demand for efficient and long-lasting supply solutions across sectors such as construction, automotive, and energy. As we delve into the top five reasons to choose 316L stainless steel pipe for your global supply needs, understanding its advantages can lead to informed decision-making and sustainable practices in your operations.

When considering materials for piping in various industrial applications, 316L stainless steel stands out for its unique combination of properties that offer significant advantages over other materials. One of the most remarkable benefits is its exceptional corrosion resistance. Unlike standard stainless steels, 316L contains molybdenum, which enhances its ability to withstand harsh environments, particularly those involving chloride exposure, making it ideal for chemical processing and marine applications.

Another compelling reason to opt for 316L stainless steel pipe is its excellent strength and durability. This material not only boasts a high tensile strength but also maintains structural integrity at elevated temperatures. As a result, it can endure heavy loads and extreme conditions without compromising performance. Additionally, 316L's remarkable weldability allows for ease of fabrication, further reducing downtime and costs associated with installation and maintenance, making it a smart choice for global supply needs.

When it comes to selecting materials for industrial applications, corrosion resistance often tops the list of priorities. This is where 316L stainless steel pipe truly excels. With a unique composition that includes molybdenum, 316L offers superior protection against harsh environmental factors, making it ideal for use in maritime industries, chemical processing, and even in waste management systems. Its ability to withstand pitting and crevice corrosion enhances its durability and longevity, ensuring that investments made in these pipes are protected over time.

Moreover, 316L stainless steel's low carbon content means it is less susceptible to carbide precipitation during welding, which can weaken the material. This feature makes it an excellent choice for projects requiring welded joints, as it maintains its structural integrity even in high-stress situations. The exceptional corrosion resistance of 316L not only extends the lifespan of the product but also minimizes the maintenance costs over its operational life, making it a smart choice for global supply needs.

| Feature | Detail | Benefit |

|---|---|---|

| Corrosion Resistance | Excellent resistance to pitting and crevice corrosion | Increased longevity and reduced maintenance costs |

| Durability | High strength-to-weight ratio | Ideal for demanding environments |

| Temperature Resistance | Maintain integrity in extreme temperatures | Versatile applications in various industries |

| Sustainability | Fully recyclable material | Supports eco-friendly initiatives |

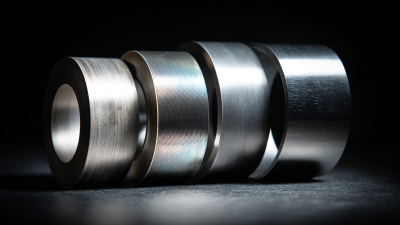

| Aesthetic Appeal | Smooth, attractive surface finish | Enhances the appearance of installations |

When it comes to selecting materials for demanding applications, 316L stainless steel pipe stands out for its exceptional durability and longevity. Known for its resistance to corrosion and high temperatures, this grade of stainless steel is pivotal in industries such as chemical processing, oil and gas, and marine environments. According to a report by the Global Stainless Steel Pipe Market, 316L stainless steel accounts for approximately 30% of the total demand due to its superior mechanical properties that enhance operational efficiency and lifespan.

The unique composition of 316L, which includes molybdenum, not only provides superior corrosion resistance compared to 304 grades but also enhances its ability to withstand extreme conditions. Research from the International Stainless Steel Forum indicates that the lifespan of 316L pipes can exceed 30 years in harsh environments, significantly reducing the need for replacements and maintenance. As industries continue to prioritize sustainability and cost-effectiveness, opting for 316L stainless steel pipes ensures both longevity and reliability, making it a top choice for global supply needs.

When considering materials for global supply needs, 316L stainless steel pipes stand out not only for their durability but also for their cost-effectiveness in the long run. The initial investment in 316L pipes can be higher compared to other alternatives, but their rust-resistant properties significantly reduce maintenance costs over time. This durability means fewer replacements and repairs, which translates into substantial savings for businesses.

Moreover, 316L stainless steel exhibits exceptional resistance to corrosion, particularly in harsh environments. This property ensures that the pipes maintain their integrity and functionality over extended periods, thus minimizing disruptions to operations and avoiding unforeseen expenses related to pipe failures. By investing in high-quality 316L stainless steel pipes, companies can enhance their operational efficiency while safeguarding their budgets, ultimately leading to a better bottom line.

When it comes to selecting the right materials for various applications, 316L stainless steel stands out due to its remarkable versatility. Unlike 304 stainless steel, 316L offers enhanced corrosion resistance, making it an ideal choice for environments that require higher durability, such as marine applications and chemical processing industries. Recent market analysis reveals that the global demand for 316 stainless steel continues to rise, driven by its superior performance characteristics in hostile environments. In fact, the growing focus on infrastructure and industrial development is expected to further augment the market size over the next few years.

Moreover, the versatility of 316L stainless steel extends to various sectors, including construction, food processing, and pharmaceuticals. The material’s resistance to chloride-induced corrosion significantly enhances its longevity, providing a reliable solution for manufacturers looking to minimize maintenance costs. As the global market dynamics evolve, the projected industrial trends indicate a robust shift towards 316L stainless steel, emphasizing its role in not just meeting but exceeding the requirements of diverse applications across the globe.