Leave Your Message

In the construction and industrial sectors, the 304 Stainless Steel Flat Bar is a crucial material. Renowned expert Dr. Michael Chen states, “The versatility of 304 Stainless Steel Flat Bar makes it an industry favorite.” This material is known for its excellent corrosion resistance and overall durability. These properties allow for extensive applications in various projects.

Many construction firms rely on 304 Stainless Steel Flat Bar for structural reinforcement. Its strength contributes to building integrity, making it a trusted choice among engineers. However, some users may overlook its specific grades. This oversight can lead to suboptimal performance in certain conditions.

Furthermore, the aesthetics of 304 Stainless Steel Flat Bar can’t be ignored. Its sleek appearance adds a modern touch to architectural designs. Yet, achieving this balance between form and function requires careful consideration. Ultimately, while 304 Stainless Steel Flat Bar is highly beneficial, the nuances of its application should not be underestimated.

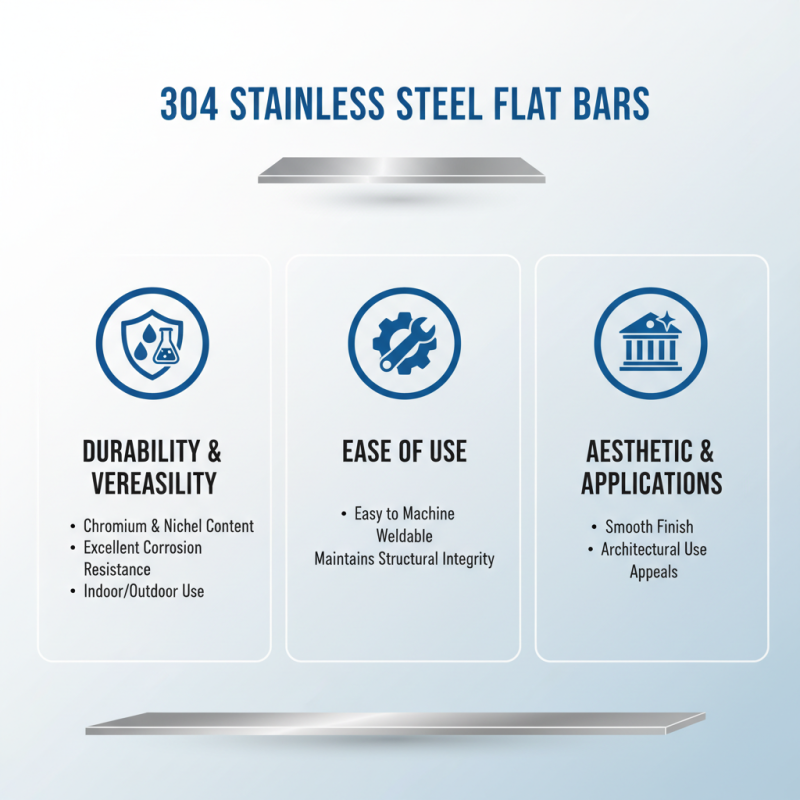

304 stainless steel flat bar is widely recognized for its durability and versatility. This material contains a mix of chromium and nickel, ensuring excellent corrosion resistance. It performs well in various environments, whether indoors or outdoors. The bar is easy to machine and can be welded without losing structural integrity. Its smooth finish enhances aesthetic appeal, making it a popular choice in architectural applications.

In construction and industry, 304 stainless steel flat bars are commonly used for frameworks, supports, and railings. They provide robust support while maintaining a sleek design. Their resistance to rust makes them suitable for food processing equipment, chemical handling, and marine applications. However, while 304 is versatile, it may not withstand high temperatures as effectively as other alloys. It's important to assess the specific requirements for any project before selecting the appropriate material. This consideration can lead to better performance and longevity in applications.

The use of 304 stainless steel flat bars has grown significantly in construction and industry. This material is favored for its excellent corrosion resistance. It can withstand harsh environments and exposure to moisture. Builders often choose it for outdoor projects. Its durability ensures a longer lifespan, reducing the need for frequent replacements.

Beyond its physical properties, 304 stainless steel is versatile. It can be easily fabricated into various shapes and sizes. This adaptability makes it suitable for everything, from frameworks to railings. However, working with stainless steel requires skilled labor. It may be tricky to weld compared to other metals. Not all workers have the same expertise, which can lead to inconsistency in projects.

Additionally, the aesthetic appeal of 304 stainless steel flat bars cannot be overlooked. They offer a sleek, modern look that enhances any structure. However, the shiny surface can show fingerprints and smudges easily. Regular maintenance is necessary to keep it looking pristine. Some might find this tedious, but the long-term benefits often outweigh the drawbacks.

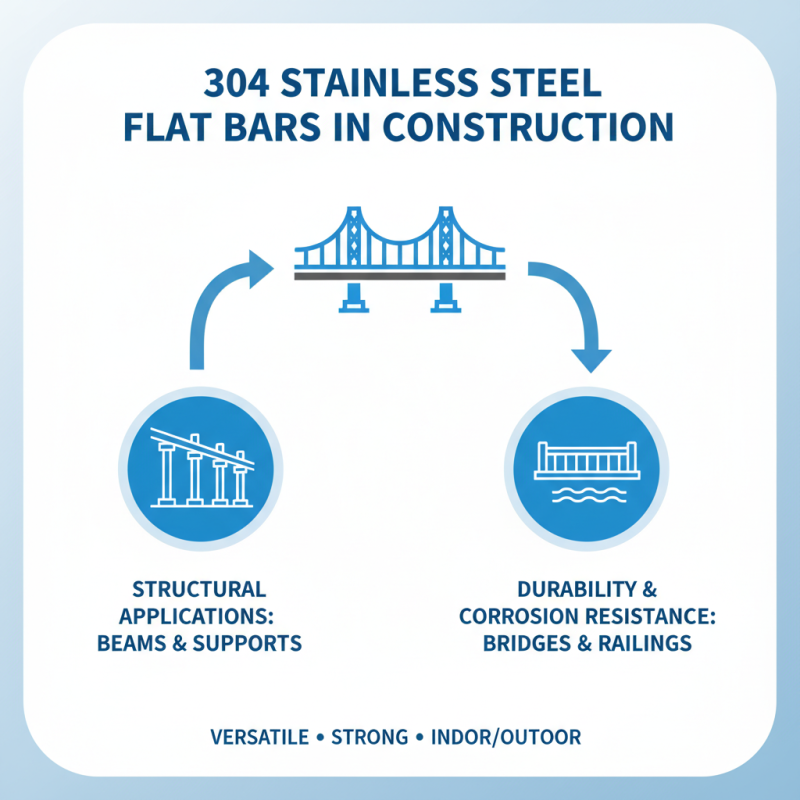

The following chart illustrates the primary applications of 304 stainless steel flat bars across various sectors in construction and industry.

304 stainless steel flat bars are widely used in the construction industry due to their versatility and strength. These bars are often utilized in structural applications, such as beams and supports. Their corrosion resistance makes them ideal for both indoor and outdoor projects. For instance, bridges and railings often incorporate 304 flat bars for added durability.

In building projects, these flat bars are also found in decorative elements. Their sleek appearance can enhance the aesthetic appeal of modern architecture. Often, they are used in handrails and staircase designs. This adds both form and function. However, not every project is suited for 304 stainless steel. In some environments, a more specialized alloy might be necessary.

Additionally, it's important to consider welding or fabrication challenges when using 304 flat bars. Improper handling can lead to issues down the line. 304 stainless steel flat bars offer many benefits, but careful planning is essential for optimal results. Observing and learning from past projects can lead to better decisions in future applications.

304 stainless steel flat bars are versatile and widely used in various industrial equipment applications. They offer excellent corrosion resistance and durability, making them suitable for harsh environments. In machine construction, these flat bars serve as support structures, providing stability to heavy machinery components. Their strength ensures reliable performance in demanding tasks.

In food processing equipment, 304 stainless steel flat bars are essential. They are easy to clean and maintain, meeting hygiene standards. This material is common in conveyor systems, ensuring seamless operation in factories. When used in frames or supports, they contribute to a long-lasting setup.

**Tips:** Always consider the weight of your design. Using lighter materials can sometimes lead to stability issues. Also, check for imperfections in the steel, as small flaws can impact performance over time. Lastly, remember to factor in thermal expansion when installing flat bars in equipment that operates at varying temperatures.

| Use Case | Industry | Advantages | Dimensions (mm) |

|---|---|---|---|

| Structural Support | Construction | High strength, corrosion resistance | 50 x 10 |

| Frames for Equipment | Manufacturing | Durable, low maintenance | 30 x 5 |

| Handrails | Commercial | Aesthetic appeal, safety | 40 x 8 |

| Supports for Machinery | Heavy Industry | Shock resistance, sturdy | 75 x 10 |

| Decorative Elements | Architecture | Versatile, attractive finish | 20 x 5 |

| Trolleys and Racks | Logistics | Lightweight, robust | 60 x 10 |

When comparing 304 stainless steel flat bars to other metal alloys, a few key differences stand out. One major advantage of 304 stainless steel is its high corrosion resistance. Reports indicate that it can withstand corrosive environments better than aluminum and carbon steel. This makes it an ideal choice in construction and industrial applications, particularly in areas exposed to moisture.

However, 304 stainless steel is not perfect. It has a lower tensile strength compared to some other alloys like 316 stainless steel or high-strength low-alloy steel. This could limit its use in high-stress applications. Additionally, the cost can be higher than alternatives. According to industry data, the price of 304 stainless steel is about 20-30% more than regular carbon steel.

Another aspect worth noting is weldability. While 304 stainless steel is generally easy to weld, issues can arise if not done properly. Poor welding techniques can lead to the formation of cracks. This is a consideration for projects demanding high structural integrity. Overall, while 304 stainless steel flat bars offer many benefits, understanding their limitations is crucial for optimal application in construction and industry.