Customer from Afghanistan asked about electro-galvanized steel wire rope

For customers from Afghanistan asking about electro-Galvanized Steel Wire Ropes, we first need to understand the basic characteristics, uses, advantages and possible purchasing considerations of electro-galvanized steel wire ropes

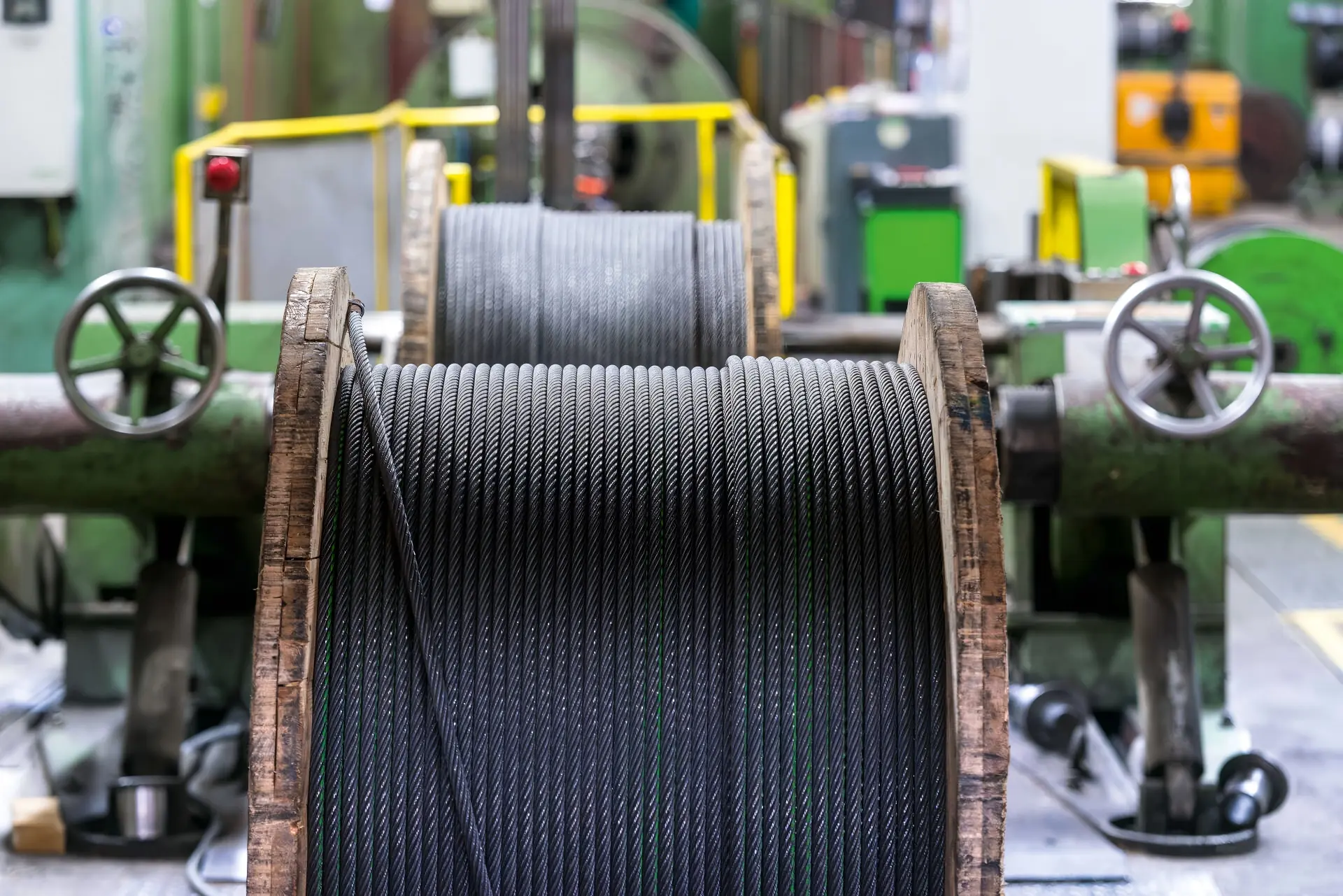

Electro-galvanized steel wire rope is a metal protective layer of zinc that is coated on the surface of the steel wire rope through an electroplating process. This protective layer effectively protects the wire rope from corrosion, thereby extending its service life and enhancing durability in various environments.

Main purpose

Lifting and hoisting: In construction, bridges, ports and other projects, electro-galvanized steel wire ropes are often used for hoisting and lifting heavy objects.

Traction and transmission: used in mining, forestry, agriculture and other industries for pulling equipment and transporting materials.

Safety system: used as a safety rope in amusement facilities, elevators, etc. to ensure the safety of equipment and personnel

Advantages

Corrosion resistance: The electro-galvanized layer provides good anti-corrosion protection and extends the service life of the steel wire rope.

High strength: The steel wire rope itself has high tensile strength and is suitable for bearing heavy loads.

Flexibility: easy to bend and twist, adaptable to various complex working conditions.

Economical: Compared with other anti-corrosion materials such as stainless steel, electro-galvanized steel wire rope is cheaper and more cost-effective.

Procurement considerations

Dimensions: Select the appropriate diameter, length and construction (e.g. rope core type) based on specific needs.

Breaking Strength: Make sure the breaking strength of the selected wire rope meets the application requirements.

Anti-corrosion performance: consider the degree of corrosion of the steel wire rope in the working environment and select the appropriate thickness of the galvanized layer.

Supplier qualifications: Choose qualified and reputable suppliers to ensure product quality and after-sales service

Advice for the Afghan market

Environmental adaptability: Considering the extreme climate conditions and working environment that may exist in Afghanistan, it is recommended to choose electro-galvanized steel wire ropes with stronger anti-corrosion properties.

Logistics and transportation: Due to the large size and weight of steel wire ropes, special attention needs to be paid to the safety and cost-effectiveness of logistics and transportation.

Local standards and regulations: Understand and comply with local standards and regulations regarding the use of wire ropes in Afghanistan.