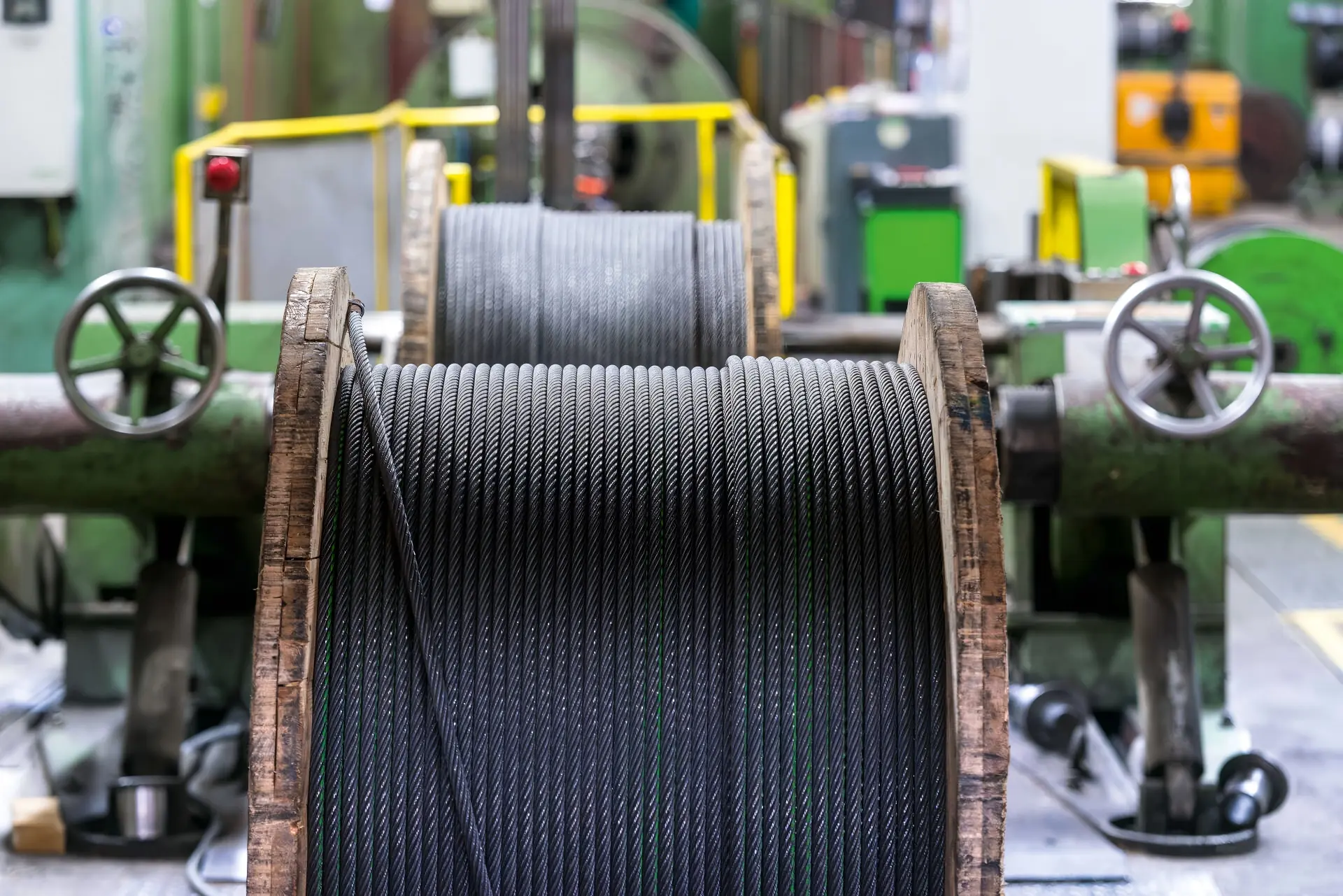

Wire ropes are divided into several categories, and what are the commonly used structures

Classification of wire ropes

Classification by structure:

Simple Structural Wire Rope: This type of wire rope consists of one or more strands, each strand is made of multiple steel wires wound inside. It has a simple structure and is relatively inexpensive, making it suitable for scenarios where the demand is not high.

Composite structure wire rope: It is made of multi-strand steel wire rope, and each strand is twisted by multiple steel wires, which has a more complex structure and superior performance.

Cable structure wire rope: On the basis of the composite structure wire rope, a head is added at each end to form a cable, which is suitable for specific rope needs

Classified by cross-sectional shape

Round wire rope: Circular in cross-section, it is the most common type of wire rope.

Flat wire rope: the cross-section is flat, which is suitable for specific space or shape requirements.

Classified by contact status

Point contact wire rope: the steel wire is in point contact with each other, such as 6X19, 6X37 and other structures, with good flexibility but slightly poor fatigue resistance.

Linear contact wire rope: The steel wires are in linear contact with each other, which has a longer service life and better fatigue resistance than point contact wire ropes.

Surface contact wire rope: The steel wires are compacted to form surface contact, and the wear resistance and fatigue resistance of this wire rope are very good

Classified according to the number of wires in the strands: such as single strands, six strands, eight strands, etc., and more complex structures such as twelve, eighteen, and thirty-four strands, the latter is also known as non-rotating wire ropes.

Classification according to twisting direction and twisting method: including right twisting, left twisting, alternate twisting (reverse twisting) and co-twisting (forward twisting), etc

Commonly used wire rope structure

In practical applications, the commonly used wire rope structures mainly include the following:

Point contact wire ropes in 6X19 and 6X37 constructions: These two structures are widely used in many occasions due to their softness and moderate price.

Wire contact wire rope: For some specific lifting and traction occasions, wire contact wire rope is favored because of its longer service life and better fatigue resistance.

Non-rotating wire rope: such as 34-strand wire rope, due to its special structure, can effectively prevent rotation during use, and is suitable for occasions with extremely high stability requirements.